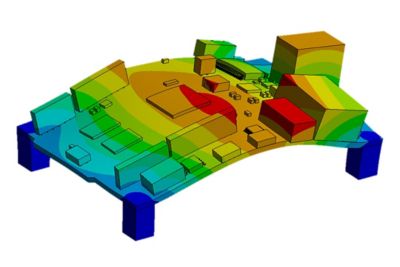

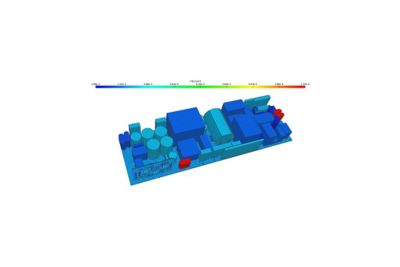

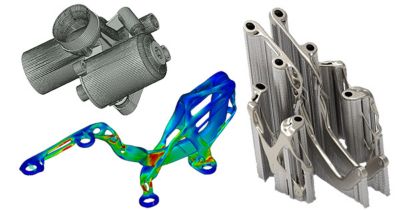

Structural Analysis Software

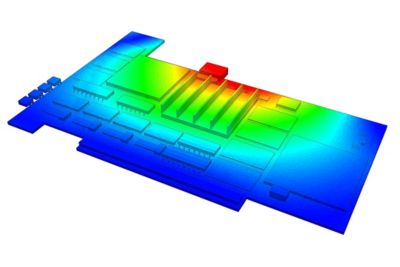

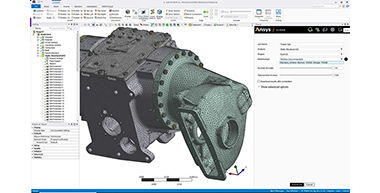

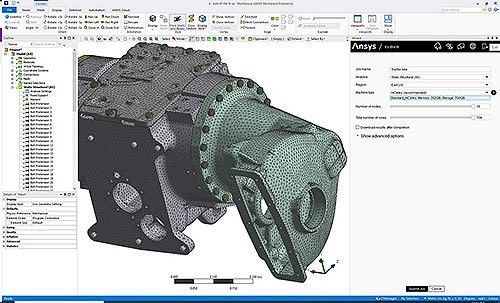

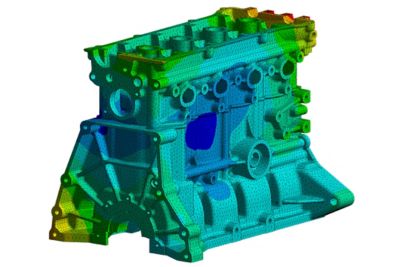

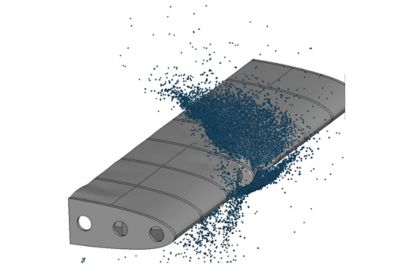

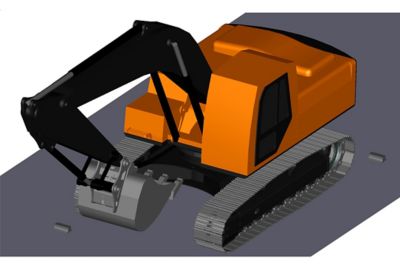

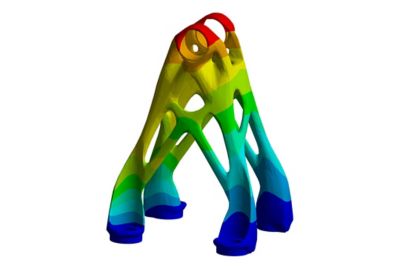

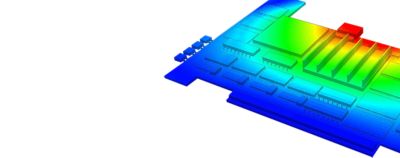

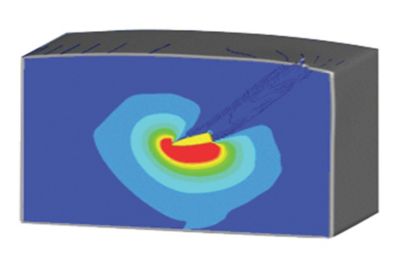

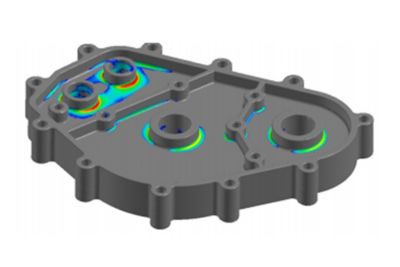

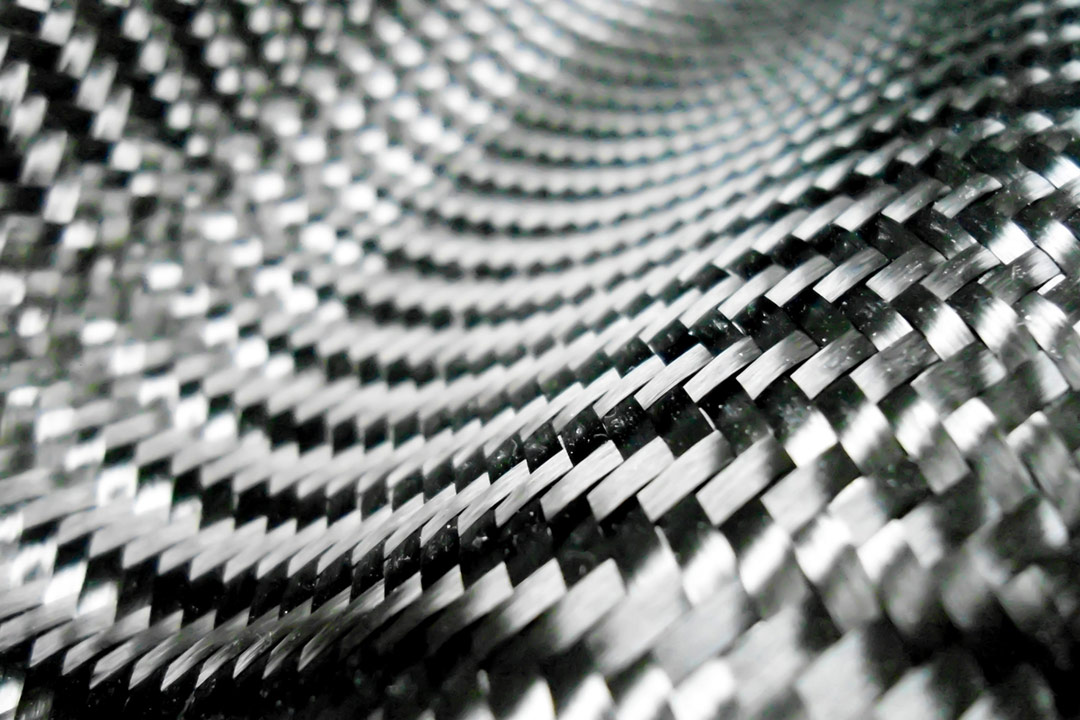

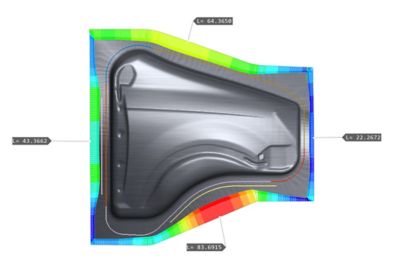

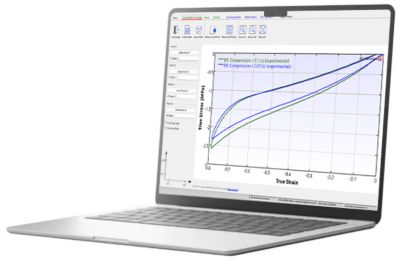

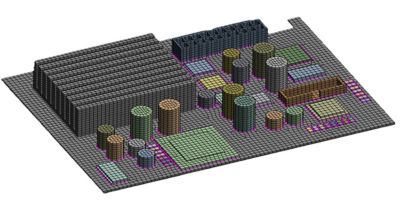

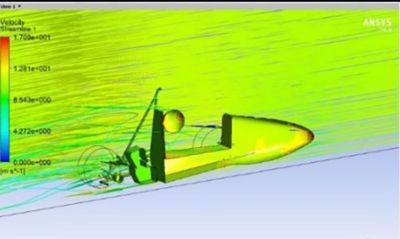

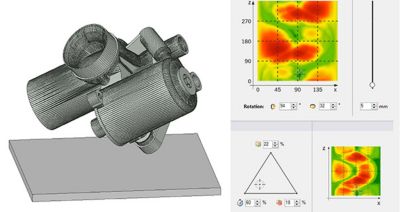

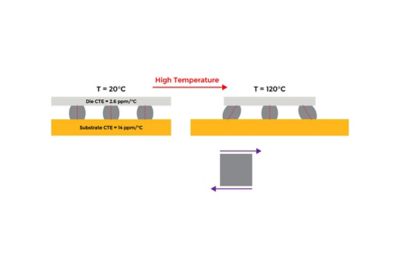

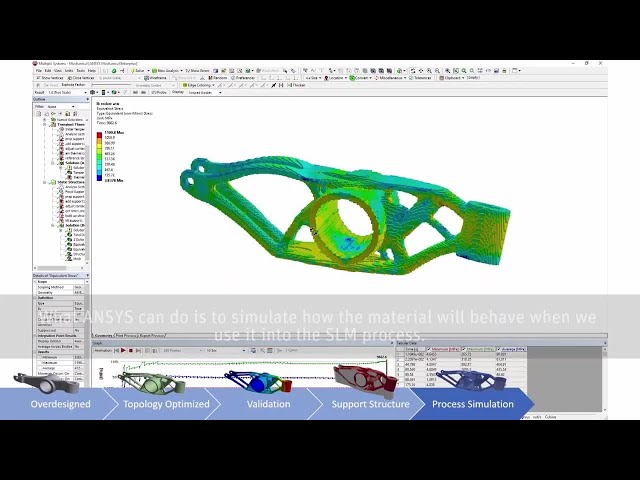

Ansys offers structural analysis software solutions that enable engineers of all levels and backgrounds to solve complex structural engineering problems faster and more efficiently. With our suite of tools, engineers can perform finite element analyses (FEA), customize and automate solutions for structural mechanics challenges and analyze multiple design scenarios. By using our software early in the design cycle, businesses can save costs, reduce the number of design cycles and bring products to market faster.