Before your company launches an electronic product, you have to think of everything: What would happen to your company’s reputation if your product underperformed? If your product failed, could it cause physical harm?

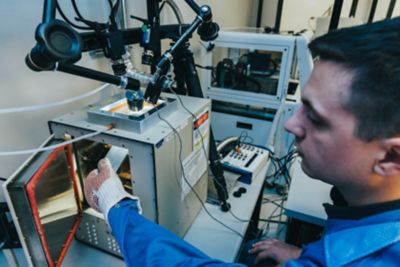

Product reliability is essential for success, and Accelerated Life Testing makes it possible to answer these questions before your launch. This process accelerates testing by increasing stress on a device to induce and accumulate damage faster than in the field. From there, you can better understand the cause of the failure. Ultimately, you can accurately simulate the extreme circumstances a device may experience in a real-world environment, leading to improved product performance, faster time to market, and reduced warranty costs.