-

-

Accédez au logiciel étudiant gratuit

Ansys donne les moyens à la prochaine génération d'ingénieurs

Les étudiants ont accès gratuitement à un logiciel de simulation de classe mondiale.

-

Connectez-vous avec Ansys maintenant !

Concevez votre avenir

Connectez-vous à Ansys pour découvrir comment la simulation peut alimenter votre prochaine percée.

Pays et régions

Espace client

Support

Communautés partenaires

Contacter le service commercial

Pour les États-Unis et le Canada

S'inscrire

Essais gratuits

Produits & Services

Apprendre

À propos d'Ansys

Back

Produits & Services

Back

Apprendre

Ansys donne les moyens à la prochaine génération d'ingénieurs

Les étudiants ont accès gratuitement à un logiciel de simulation de classe mondiale.

Back

À propos d'Ansys

Concevez votre avenir

Connectez-vous à Ansys pour découvrir comment la simulation peut alimenter votre prochaine percée.

Espace client

Support

Communautés partenaires

Contacter le service commercial

Pour les États-Unis et le Canada

S'inscrire

Essais gratuits

INFORMATIONS SUR LE SUJET

Qu'est-ce que l'électronique automobile ?

L'électronique automobile est un système automobile qui traite et modifie les signaux électriques et l'alimentation pour surveiller, contrôler et exécuter des fonctions dans le véhicule. Les voitures modernes utilisent un réseau complexe de systèmes électroniques interconnectés pour améliorer la sécurité, l'efficacité, les performances, le confort et l'expérience utilisateur. Les véhicules de tourisme actuels peuvent comporter jusqu'à 100 modules électroniques, avec plus de 200 modules dans les voitures électriques ou hybrides. La présence d'appareils électroniques dans les véhicules n'augmentera qu'avec les avancées en matière de technologie des véhicules électriques (EV), de conduite autonome et d'amélioration de la connectivité. Cela constitue de nouveaux défis pour les ingénieurs qui conçoivent et construisent ces véhicules.

L'importance croissante de l'électronique automobile

L'utilisation de l'électricité dans les véhicules a commencé très tôt avec les phares électriques, puis avec des moteurs électriques pour démarrer le véhicule ou faire fonctionner les essuie-glaces. Le développement de semi-conducteurs discrets tels que les transistors et les diodes a permis aux constructeurs automobiles d'ajouter des alternateurs et une injection de carburant électronique simple pour gagner en efficacité.

Par la suite, lorsque l'industrie a adopté les circuits intégrés, des unités de commande électronique (ECU) multipuce ont été intégrées dans les années 80 afin d'améliorer le contrôle du moteur, les systèmes de freinage antiblocage (ABS) et les modules de contrôle électronique de stabilité (ESC). Au 21e siècle, les constructeurs automobiles ont intensifié leur utilisation de l'électronique automobile, transformant les voitures en ordinateurs sur roues et se tournant vers des véhicules définis par logiciel.

Cinq tendances du secteur sont à l'origine de l'importance croissante des systèmes électroniques automobiles dans les véhicules :

- Sécurité : Les gouvernements, les consommateurs et l'industrie automobile elle-même continuent de repousser les limites des attentes en matière de sécurité. Les capteurs, combinés à des systèmes intelligents, peuvent identifier et traiter les dangers beaucoup plus rapidement et plus efficacement que les conducteurs humains. Les fabricants doivent inclure ces fonctionnalités pour se conformer à des toujours plus exigeantes et répondre à la demande des consommateurs.

- Rendement : Les exigences en matière d'amélioration de l'efficacité ont également augmenté au fil du temps, y compris des exigences plus strictes en matière d'émissions. Les fabricants et les fournisseurs ont ajouté des systèmes de contrôle et de surveillance électroniques en temps réel à chaque élément du groupe motopropulseur afin d'améliorer le kilométrage et de réduire les polluants tout en maintenant les performances.

- Expérience utilisateur : Comme l'électronique a transformé tous les aspects du quotidien, les conducteurs et les passagers s'attendent à la même connectivité, la même facilité d'utilisation et les mêmes capacités que celles offertes par l'électronique grand public.

- Électrification : La transition des véhicules à moteur à combustion interne (ICE) aux véhicules hybrides et entièrement électriques peut doubler le nombre de modules électroniques d'une voiture. Dans le même temps, la haute tension des groupes motopropulseurs électriques augmente la complexité et les problèmes de sécurité fonctionnelle des véhicules utilisant la propulsion électrique.

- Conduite autonome : L'évolution rapide des véhicules semi-autonomes vers des véhicules entièrement autonomes accroît également la dépendance à l'électronique dans le secteur automobile. Les fonctions de conduite autonome courantes, telles que le régulateur de vitesse adaptatif, combinent capteurs, calculs et commande moteur pour automatiser les tâches du conducteur. À mesure que les constructeurs automobiles intègrent davantage d'automatisation, l'électronique des véhicules se développe.

Les composants de l'électronique automobile

Les différents systèmes électroniques d'un véhicule se composent de plusieurs composants électroniques et des connexions entre eux. Chaque composant a ses propres besoins en termes de conception, de fonctionnement et de maintenance.

Voici une liste des types de composants électroniques automobiles les plus courants :

- Capteurs : Les capteurs mesurent les valeurs physiques et les transmettent à d'autres systèmes. Ils peuvent mesurer des valeurs à l'intérieur ou à l'extérieur d'un véhicule, comme la pression, la vitesse, l'emplacement, la température, la circulation et la proximité. Des capteurs plus sophistiqués, tels que les radars, les dispositifs ultrasoniques, la détection et la télémétrie par la lumière (lidar), peuvent également fournir la distance, la forme, l'azimut et la position d'élévation d'une cible. Les signaux de tous ces capteurs peuvent être transmis à des systèmes d'intelligence artificielle (IA) qui peuvent ensuite utiliser la fusion de capteurs pour fournir au véhicule une meilleure connaissance de la situation.

- Actionneurs : Au fil du temps, les constructeurs automobiles ont remplacé de nombreuses liaisons mécaniques par des actionneurs, des dispositifs tels que des solénoïdes et des moteurs qui transforment un signal électrique en une force qui déplace un objet mécanique. Cela peut être aussi simple que l'ouverture et la fermeture d'une buse d'aération du système de climatisation ou aussi sophistiqué que le changement de vitesse dans la transmission.

- ECU : Les ECU collectent et traitent les données des capteurs et les commandes de l'opérateur pour contrôler les différentes fonctions du véhicule. Comme les ordinateurs, les ECU utilisent le logiciel et le micrologiciel pour faire fonctionner le véhicule.

- Électronique de puissance : L'électronique de puissance fait référence aux modules de commande, aux alimentations, aux convertisseurs de puissance et aux faisceaux de câblage qui transportent des tensions élevées. Elle fournit une alimentation électrique aux systèmes les plus demandés, tels que le démarreur, les chauffages électriques ou les moteurs électriques, et gère l'état de charge de la batterie.

- Réseaux de communication : Tous ces modules et leurs sous-systèmes communiquent via des réseaux câblés en utilisant des protocoles tels que CAN Bus, LIN, FlexRay et Ethernet. En outre, les réseaux de communication offrent une connectivité Véhicule-à-Tout (V2X) sans fil pour les smartphones, Internet, les GPS, les infrastructures ou les autres véhicules. Ce groupe de composants est parfois appelé télématique.

- Composants de l'interface utilisateur : Les conducteurs et les passagers interagissent avec les véhicules via les composants de l'interface utilisateur, notamment les boutons, les systèmes d'infodivertissement, les affichages tête haute, les composants du tableau de bord et les écrans d'affichage.

Les différentes classifications des modules dans l'électronique automobile

L'un des moyens pour l'industrie de suivre le nombre croissant de systèmes électroniques dans les véhicules est de les répartir dans différentes classifications en fonction de leurs fonctions.

Voici une liste des classifications standard et des composants les plus courants dans chaque catégorie :

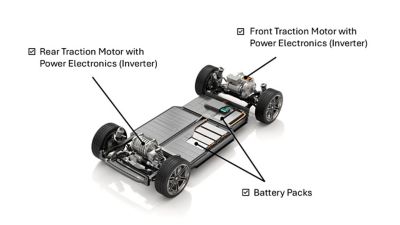

Le groupe motopropulseur d'un véhicule électrique (EV) se compose de batteries, de moteurs et d'électronique de puissance.

Un groupe motopropulseur est constitué des systèmes d'une voiture qui fournissent le couple aux roues. Du réservoir de carburant au tuyau d'échappement en passant par les batteries et les moteurs d'un véhicule électrique, c'est le groupe motopropulseur qui utilise le plus d'énergie. La plupart des composants électroniques de cette classification se concentrent donc sur le rendement énergétique, les performances du véhicule ou la réduction des émissions.

Les modules électroniques les plus courants des groupes motopropulseurs ICE sont les suivants :

- Commandes électroniques du carburant

- Commandes des émissions

- Unités de commande du moteur

- Gestion du moteur

- Capteurs du moteur

- Commandes de transmission

Outre la plupart de ces composants, les véhicules hybrides et électriques utilisent des modules électroniques d'alimentation, notamment :

- Systèmes de gestion de batteries

- Commandes de température de la batterie

- Moteurs d'entraînement

- Composants électroniques de recharge

- Inverseurs et régulateurs de tension

Systèmes de sécurité

Les équipes de conception peuvent tirer parti de l’augmentation des capacités des capteurs et de l'edge computing dans les ECU pour améliorer la sécurité des véhicules et accroître la complexité des modules.

Parmi les systèmes de sécurité les plus courants, on peut citer :

- Airbags

- Systèmes de freinage antiblocage

- Contrôle antipatinage (ASRS)

- Caméras de recul

- Capteurs d'angle mort

- Détection et prévention des collisions

- Freinage d'urgence

- Aide au démarrage en côte (HSA)

- Avertissements de changement de voie

- Surveillance de la pression des pneus

- Systèmes de contrôle de traction (TCS)

Système d'infodivertissement

Les appareils électroniques qui fournissent des informations ou des divertissements aux passagers sont classés dans la catégorie des systèmes d'infodivertissement. Ils comprennent :

- Connectivité haut débit

- Systèmes de divertissement

- Tableaux de bord

- Systèmes de navigation

- Connectivité smartphone

- Haut-parleurs et microphones

- Dispositifs d'interface utilisateur

- Diagnostics du véhicule

- Configuration des fonctionnalités du véhicule

Composants électroniques du châssis

Les systèmes électroniques automobiles qui n'appartiennent pas aux catégories précédentes sont appelés composants électroniques de châssis. Cependant, l'automatisation et l'intégration accrues brouillent les frontières entre l'électronique de sécurité et l'électronique du châssis.

Les modules électroniques du châssis incluent :

- Phares adaptatifs

- Systèmes avancés d'aide à la conduite (ADAS)

- Éclairage de la cabine

- Climatisation

- Freinage électronique

- Direction électronique

- Entrée sans clé

- Systèmes d'éclairage

- Contrôle de suspension

Pilotage la conception de l’électronique automobile grâce à la simulation

Les ingénieurs peuvent utiliser des outils de simulation tout au long du processus de conception pour répondre aux complexités et aux défis croissants de l'électronique automobile. Les équipes ne peuvent pas se permettre d'attendre les prototypes pour tester leurs idées et vérifier si les systèmes électroniques sont suffisamment robustes pour les charges thermiques, structurelles et électromagnétiques.

Les fabricants d'équipements d'origine (OEM) et leurs fournisseurs appliquent la simulation à chaque composant, module et assemblage du système électrique d'un véhicule. Ce prototypage virtuel améliore les performances, réduit les réclamations au titre de la garantie, vérifie la sécurité, réduit les coûts et accélère la mise sur le marché des nouvelles conceptions.

La plupart des tâches de simulation peuvent être classées dans l'un de ces quatre domaines :

1. Fonctionnalité

L'application initiale de la simulation consiste à aider les ingénieurs à concevoir des véhicules pour tester le fonctionnement de leurs composants. La réponse de chaque module peut être conçue et testée virtuellement au fur et à mesure que la conception est créée au niveau des composants, des sous-systèmes et des systèmes. Les ingénieurs utilisent un outil, tel que le solveur de champ électromagnétique avancé Ansys Maxwell, pour concevoir des dispositifs électromécaniques tels que des moteurs et des actionneurs ou des systèmes électroniques de puissance, comme des transformateurs et des régulateurs de tension. Les concepteurs de systèmes optiques répondent aux exigences des objectifs des capteurs basés sur la lumière avec des plateformes de simulation optique telles que le logiciel de conception et d'analyse de systèmes optiques Ansys Zemax OpticStudio. Les concepteurs d'intérieur peuvent également observer l'aspect et l'ambiance de l'éclairage de l'habitacle avec un produit tel que le logiciel de simulation optique et d'éclairage intégré CAD Ansys Speos.

2. Optimisation

Une fois qu'ils ont satisfait aux exigences fonctionnelles d'un appareil électronique pour une application automobile, les ingénieurs doivent optimiser la conception. C'est lors de cette étape qu'ils améliorent l'efficacité, réduisent les émissions et optimisent les performances.

Ils peuvent utiliser un outil doté de fonctionnalités tel que l'environnement de développement basé sur un modèle Ansys SCADE Suite pour les logiciels intégrés essentiels afin de modifier le micrologiciel d'une ECU. Ou peut-être utiliseront-ils le logiciel de simulation électromagnétique haute fréquence Ansys HFSS pour concevoir et optimiser une antenne pour les applications GPS. Cette antenne peut ensuite être couplée à une plateforme de simulation de mission numérique telle que le logiciel d'ingénierie de mission numérique Ansys Systems Tool Kit (STK) pour s'assurer que l'antenne GPS du système d'infodivertissement reçoit le signal le plus puissant possible dans de nombreuses situations de conduite.

Ensuite, une fois chaque module optimisé, les ingénieurs peuvent déployer une plateforme d'optimisation complète comme le logiciel d'intégration des processus et d'optimisation de conception Ansys OptiSLang pour atteindre leurs objectifs rapidement et efficacement.

3. Fiabilité

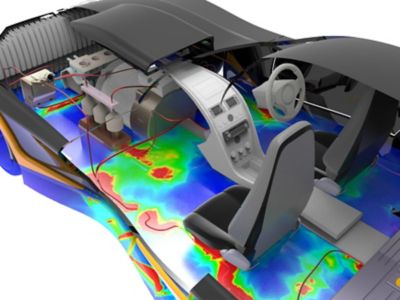

L'un des aspects les plus importants de la conception automobile réside dans la fiabilité. Les propriétaires s'attendent à ce que leurs véhicules fonctionnent correctement après avoir accumulé de nombreux kilomètres, ce qui est normal pour un véhicule en bon état. Mais la chaleur, les vibrations, les chocs et le bruit électromagnétique dans les automobiles rendent difficiles l'atteinte de ces objectifs de robustesse élevés, c'est pourquoi les équipes d'ingénieurs utilisent des outils de simulation structurelle, thermique et électromagnétique pour soumettre leurs systèmes électroniques automobiles à des tests virtuels rigoureux.

Ils peuvent déployer le logiciel d'analyse structurelle par éléments finis Ansys Mechanical pour l'évaluation thermique, structurelle et vibratoire afin de s'assurer que tous les composants, ainsi que les connexions physiques et électriques, répondent aux exigences de durée de vie du véhicule et fonctionnent durablement. En ce qui concerne les circuits imprimés (PCB) et les ensembles de circuits intégrés dans les ECU, ils peuvent s'appuyer sur un outil de simulation spécialisé dans l'électronique, tel que le Ansys Icepak, un logiciel de simulation de refroidissement électronique, et Ansys Sherlock, un logiciel de prévision de fiabilité électronique.

4. Interférence

logiciel de modélisation et de simulation électromagnétique

Les interférences électromagnétiques et la compatibilité électromagnétique (EMI/EMC) constituent un défi de plus en plus important pour l'électronique automobile, en particulier lorsque les voitures sont équipées de systèmes haute tension, comme c'est le cas dans les véhicules électriques. Le nombre de composants haute fréquence et de signaux numériques haute vitesse qui se déplacent d'un module à l'autre, la tension des systèmes de batterie électrique et l'utilisation d'antennes augmentent. Les ingénieurs utilisent des outils tels que le logiciel de simulation électromagnétique de circuits imprimés et de boîtiers Ansys SIwave pour résoudre les problèmes d'intégrité du signal et de l'alimentation sur les circuits imprimés utilisés dans une ECU. Ils peuvent également utiliser le logiciel de modélisation et de simulation électromagnétique Ansys EMC Plus pour étudier la façon dont les ondes haute fréquence interagissent entre le câblage et les fils. Vous pouvez même l'utiliser pour modéliser l'impact de la foudre sur les systèmes électroniques d'une voiture.

Ressources connexes

Commençons

Si vous êtes confronté à des défis d'ingénierie, notre équipe est là pour vous aider. Forts de notre expérience et de notre engagement en faveur de l'innovation, nous vous invitons à nous contacter. Collaborons pour transformer vos obstacles techniques en opportunités de croissance et de réussite. Contactez-nous dès aujourd'hui pour entamer la conversation.