Case Study

-

-

Accédez au logiciel étudiant gratuit

Ansys donne les moyens à la prochaine génération d'ingénieurs

Les étudiants ont accès gratuitement à un logiciel de simulation de classe mondiale.

-

Connectez-vous avec Ansys maintenant !

Concevez votre avenir

Connectez-vous à Ansys pour découvrir comment la simulation peut alimenter votre prochaine percée.

Pays et régions

Espace client

Support

Communautés partenaires

Contacter le service commercial

Pour les États-Unis et le Canada

S'inscrire

Essais gratuits

Produits & Services

Apprendre

À propos d'Ansys

Back

Produits & Services

Back

Apprendre

Ansys donne les moyens à la prochaine génération d'ingénieurs

Les étudiants ont accès gratuitement à un logiciel de simulation de classe mondiale.

Back

À propos d'Ansys

Concevez votre avenir

Connectez-vous à Ansys pour découvrir comment la simulation peut alimenter votre prochaine percée.

Espace client

Support

Communautés partenaires

Contacter le service commercial

Pour les États-Unis et le Canada

S'inscrire

Essais gratuits

“Using Ansys Fluent software, we conducted aerodynamic simulations of the aeroshell. The greatest advantage of Ansys is its excellent usability — its interactive interface makes it easy to design the fluid domain, set boundary conditions, define simulation parameters, and select models. The integrated preprocessing and post-processing tools are powerful, allowing us to check and repair models as well as visualize results effectively. The comprehensive user guide not only explains software usage but also provides valuable theoretical background. Overall, Ansys is intuitive, easy to operate, delivers accurate results, and offers outstanding visualization capabilities.”

— Jiamu Chu

Mechanical Team Member, Ecogenium e.V.

The Shell Eco-marathon is all about driving as efficiently as possible. In this competition, student teams all over the world design cars to compete in different energy categories and two vehicle classes. Student team Ecogenium e.V., from RWTH Aachen University in Aachen, Germany, participates in the Urban Concept Hydrogen Fuel Cell category, which involves developing a car that achieves the lowest hydrogen usage while driving the longest distance.

From a mechanical point of view, the most important factors are weight, rolling resistance, and aerodynamics. In previous years, the team was adamant about designing a safe and reliable car at the cost of increasing weight. Through computational fluid dynamics (CFD) simulations, the team was able to see where they could shave off weight while maintaining reliability. At the same time, aerodynamic simulations were used to further improve the aeroshell and reduce air resistance.

Ecogenium e.V. team with their 2025 car

Challenges

As students, the team’s experience with simulation, software, and design was limited, especially because the team was founded just a few years ago. When Ecogenium e.V. started to develop their next car, they put more emphasis on weight savings. While saving weight was important to the team, they wanted to make sure the chassis was safe and that it could withstand multiple forces while driving. The Ansys Composite PrepPost solver inside Ansys Mechanical software helped with this task, as it was intuitive to use and helped with comparing many different designs simultaneously.

For aerodynamics, the team decided to pursue a new design philosophy by aiming to improve the underfloor and designing a diffuser. This was the first time the students designed this component, so they had to go through many versions of the aeroshell and compare the results through simulation. Through Fluent software and the Composite PrepPost solver, Ecogenium e.V. not only made a lot of progress for their designs, but they also gained valuable experience and knowledge.

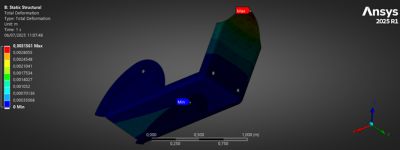

Simulation of the forces cars are judged upon in the Shell Eco-marathon. The team also tested for acceleration, braking, and crashes.

Engineering Solutions

For the chassis, Ecogenium e.V. simulated the forces cars are judged upon in the competition, as specified by the Shell Eco-marathon rulebook. In addition, they simulated braking, acceleration, and crashes to fully understand the performance of the new design.

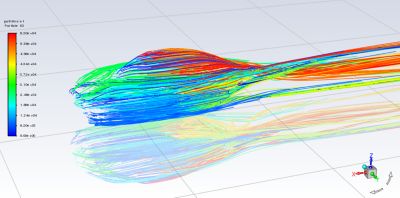

The overall outer shape of the aeroshell is fixed early in the design process, and CFD serves to highlight local issues such as separation regions or recirculation bubbles. In the simulations of the 2025 car, the main factor increasing drag coefficient (Cd) is the large recirculation zone behind the aeroshell and below the car. The team used the simulation results as a guide for adjustments to these regions to smooth out the design and delay separations.

Computational fluid dynamics (CFD) simulation of aeroshell external aerodynamics shows the pathlines around the aeroshell. The flow attaches smoothly over the upper surface, indicating that the front shape effectively guides the incoming airflow. In the rear region, the pathlines diverge and form a wake, which increases drag.

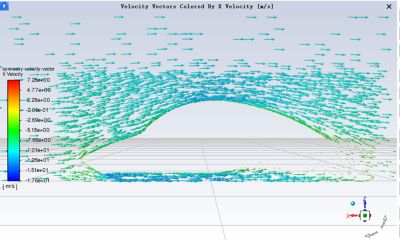

Simulation showing the velocity vectors on the symmetry plane. The result reveals that the flow above the shell accelerates smoothly before losing momentum downstream. These features confirm that while the aeroshell performs well in shaping the front flow, it experiences drawbacks at the rear.

Benefits

Ecogenium e.V. focused on weight reduction for their next car, bringing the chassis weight from 22 kg to 15 kg through multiple design iterations. Using the Composite PrepPost solver, they compared designs and ensured the chassis remained safe and structurally sound.

For aerodynamics, the students redesigned the underfloor and added a diffuser. Using Fluent software, the team optimized their design, improving the Cd from 0.181 to 0.145. These tools helped Ecogenium e.V. make significant design progress while gaining valuable experience.

Ultimately, the team achieved a result of more than 2,500 kilometers per kilogram (km/kg) with their 2025 car, which was nearly double that of the previous year’s result. In comparison, a normal hydrogen car achieves ~80 km/kg. This result earned them second place in the Urban Concept Hydrogen Fuel Cell category of the competition.

Commençons

Si vous êtes confronté à des défis d'ingénierie, notre équipe est là pour vous aider. Forts de notre expérience et de notre engagement en faveur de l'innovation, nous vous invitons à nous contacter. Collaborons pour transformer vos obstacles techniques en opportunités de croissance et de réussite. Contactez-nous dès aujourd'hui pour entamer la conversation.