Powering Leading-edge E-mobility

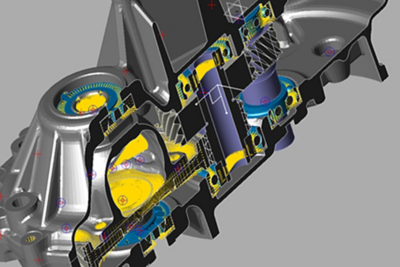

Together, Ansys and Porsche Motorsport are leading the field in the race to next-generation e-mobility. As Porsche's Official Simulation Partner of the TAG Heuer Porsche Formula E Team, Ansys is powering the design of the automaker’s first-ever, fully electric race car — the Porsche 99X Electric.

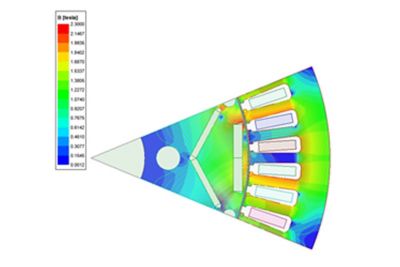

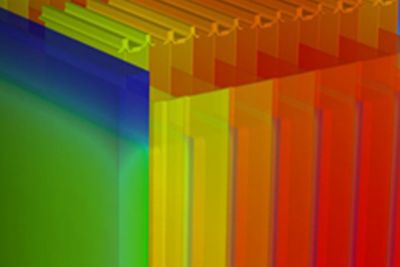

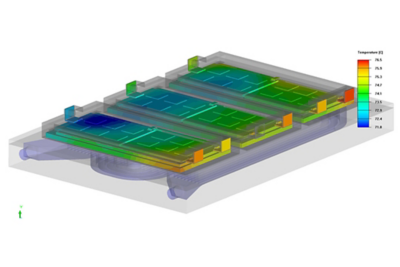

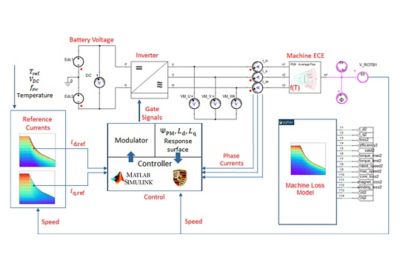

This exciting partnership pairs our industry-leading engineering simulation with Porsche’s high-performance automotive engineering, in the development of the Porsche E-Performance Powertrain. Our electrification solutions support Porsche Motorsport’s mission to maximize powertrain efficiency in its electric race cars — and passenger electric vehicles.