-

-

Accédez au logiciel étudiant gratuit

Ansys donne les moyens à la prochaine génération d'ingénieurs

Les étudiants ont accès gratuitement à un logiciel de simulation de classe mondiale.

-

Connectez-vous avec Ansys maintenant !

Concevez votre avenir

Connectez-vous à Ansys pour découvrir comment la simulation peut alimenter votre prochaine percée.

Pays et régions

Espace client

Support

Communautés partenaires

Contacter le service commercial

Pour les États-Unis et le Canada

S'inscrire

Essais gratuits

Produits & Services

Apprendre

À propos d'Ansys

Back

Produits & Services

Back

Apprendre

Ansys donne les moyens à la prochaine génération d'ingénieurs

Les étudiants ont accès gratuitement à un logiciel de simulation de classe mondiale.

Back

À propos d'Ansys

Concevez votre avenir

Connectez-vous à Ansys pour découvrir comment la simulation peut alimenter votre prochaine percée.

Espace client

Support

Communautés partenaires

Contacter le service commercial

Pour les États-Unis et le Canada

S'inscrire

Essais gratuits

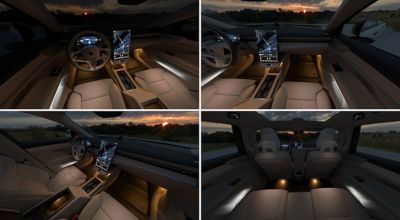

Design at Volvo Cars starts with people. For decades, the Swedish brand has placed human needs, safety, and comfort at the heart of every design decision. Volvo’s Scandanavian design language balances elegance, light, and proportion to create a sense of calm, confidence, and trust for every occupant.

Interior lighting is a clear expression of this philosophy. Each carefully integrated lighting solution is developed to support different moods and respond to customer needs, flowing seamlessly without distraction while remaining both decorative and functional.

Volvo offers a range of ambient lighting settings designed to elevate the driving experience through subtle adjustments in intensity and color. Once technical and aesthetic requirements are defined for a vehicle program, the design team aligns lighting objectives with key functional elements. Visibility and clarity are prioritized in areas such as footwells, glove compartments, and storage spaces, while material properties, geometries, and reflective behavior are thoughtfully considered in every detail.

Advanced optical simulations allow these lighting concepts to be explored and refined long before physical prototypes are produced. Using Ansys software, Volvo can accurately render mechanical and optical designs for interior lighting components — ensuring that each solution supports the distinctive, calming brand experience customers have come to expect from a Volvo.

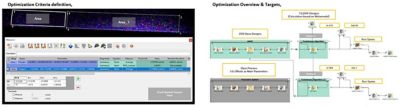

An optimization loop setup. Pictured left: An example target with two areas in which “Area” is intended not to have light and “Area 1” is intended to concentrate most of the light. Pictured right: A diagram of the optimization flow overview.

When Ansys Software Is Your Guide

An important element of Volvo’s optical design exploration is the light guide, an optical device used in automotive engineering to convey light from a light source to a certain point with minimal loss or dispersion.

Automotive light guides are generally composed of optical-grade materials that include acrylic resins, epoxies, and glass, which are applied to interior surfaces to eliminate unwanted reflections or brightness. Their design is crucial to meeting Volvo’s objectives for efficient light distribution and power consumption, as well as the overall cockpit visual experience.

“Interior light contributes to a vehicle’s fundamental purpose by enhancing content surfaces for the user to interact better with the parts,” says Gerardo Morales, interior light design and simulation engineer at Volvo Cars. “We consider as much accuracy as possible when it comes to the materials that are being simulated to understand the physics around them when interacting with light to try to maximize [enhancing their characteristics] as much as possible.”

To fulfill a design intent requires meeting multiple criteria during program development. Engineers are tasked with checking their designs in context and understanding how they work in combination with other light sources in the vehicle.

Ansys Speos computer-aided design (CAD)-integrated optical and lighting simulation software and Ansys optiSLang process integration and design optimization software are among several of the advanced tools Volvo uses as part of a collaborative workflow to navigate lighting challenges involving light guides.

- Speos software enables detailed evaluations of light behavior across different materials and conditions.

- optiSLang software is used to automate extensive sensitivity analyses to pinpoint how various design parameters affect overall performance.

Generally, Volvo’s optical work involves defining the main inputs, creating the geometry, running a simulation, understanding that simulation, and then exporting the result. Replicating this effort a number of times in a simulation environment helps establish a deeper understanding of the lighting involved.

"Working with three different light guides in a space described with parameters like length, radius, offset, and start angle, presents endless possibilities,” says Gerardo Morales, interior light design and simulation engineer at Volvo Cars. “All of those combinations will have a different result in the car. And theoretically, all of them will be correct because they will fulfill something. In the end, simulation helps us work through these possibilities to find the best solution."

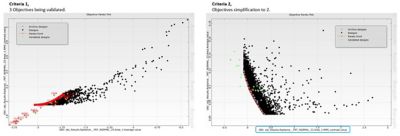

An example of the data received during sensitivity analysis of the process, where multiple options for detailed summaries are available for the user to understand the influence of the selected parameters to be studied

Reflecting on Light Criteria in One Multidisciplinary Multiphysics Workflow

One simulation-driven workflow in particular was helpful in understanding reflections in a specific area of a door panel related to the use of a light guide. In this instance, the target had a higher concentration of light in one area with respect to another. Implementation of the workflow involved a series of automated steps.

First, a base process was created that was replicated several times in optiSLang software. Working from that base process, the tool then performed a sensitivity analysis to later inform optimization analysis.

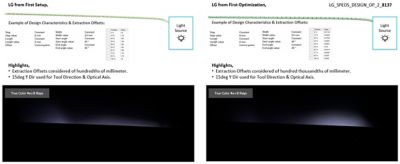

Python-based code scripting was used to create a light guide within Speos software by controlling different light guide prism design parameters, including start and end points, step value (i.e., the increment or difference between prisms), and offset definition (or the shift of a prism from the center of an optical axis).

A summary of the optimization analysis of the process, where the total computed designs are put together in a Pareto plot as per the criteria defined, and the validated designs are for the user to assess and choose from

Once the code was created, the main parameters of interest to the engineering team could be selected for design exploration later. In this instance, the parameters were based on offset depth values. The resulting script was then linked to the Speos project, where the light guide was created and connected to a simulation analysis evaluating the target sensors.

The simulation was automated to run in Speos software, and responses were extracted and analyzed as targets for comparison. Finally, another short script was run to convert those results into images that enabled Volvo to capture the design progression visually later on.

In the end, it was up to the user to assess from the filtered and validated designs those that align more closely with the previously mentioned criteria (criteria related to the concentration of light along the door panel and its affinity to cause reflections). Methods like these help the Volvo team navigate complex lighting scenarios to further refine their designs, ensuring both technical and aesthetic objectives are met in the final product.

From an initial example where the areas are defined, these images capture test results of one of the optical designs from the optimization process that fulfills the requirements for an area with less or no light and an area of mostly concentrated light.

Automated To Run 300 Unique Optical Designs Per Day

The entire workflow mentioned above is used to consider a single criterion of a light guide design. To further optimize a given design might involve running the process 200-300 times to extract additional data based on previously defined responses and criteria. This is where optiSLang software is particularly valuable.

optiSLang software automates Volvo’s simulation workflows through parametric model integration to enable detailed analysis of light guide properties, relevant parameters, and their impact on different aspects of the cockpit. Through process integration and design optimization (PIDO), the software can be used to connect multiple tools enabling a multi-disciplinary multiphysics workflow that can accelerate analysis.

“For us, optiSLang software is a complementary tool that saves time validating the variety and influence of a certain product characteristic through several iterations,” says Ranga Raju Mohanapu, illumination simulation engineer at Volvo Cars. “Without the tool, one light guide design and simulation might take approximately 30 minutes to an hour, producing six to eight combinations per day. With optiSLang software, we can analyze up to 300 light guide designs in just one day.”

Design execution at an accelerated pace is particularly beneficial, given the pace of innovation in the automotive industry, in which automakers are working ahead on lighting solutions as far out as the 2029 model year within incredibly short time frames. And, with the significant speedup enabled by Ansys software, there’s plenty of time for making new discoveries.

“Designing light-related parts is a process of infinite learning and endless possibilities,” says Morales. “Software like Ansys Speos and Ansys optiSLang offers such a wide variety of options for analysis that it might be that I get to learn something new about light guide design every day, every time I open my computer to do my job.”

Learn more about Speos software and optiSLang software.

Just for you. We have some additional resources you may enjoy.

“Without the tool, one light guide design and simulation might take approximately 30 minutes to an hour, producing six to eight combinations per day. With optiSLang software, we can analyze up to 300 light guide designs in just one day.”

— Ranga Raju Mohanapu, illumination simulation engineer, Volvo Cars

The Advantage Blog

The Ansys Advantage blog, featuring contributions from Ansys and other technology experts, keeps you updated on how Ansys simulation is powering innovation that drives human advancement.