-

-

Accédez au logiciel étudiant gratuit

Ansys donne les moyens à la prochaine génération d'ingénieurs

Les étudiants ont accès gratuitement à un logiciel de simulation de classe mondiale.

-

Connectez-vous avec Ansys maintenant !

Concevez votre avenir

Connectez-vous à Ansys pour découvrir comment la simulation peut alimenter votre prochaine percée.

Pays et régions

Espace client

Support

Communautés partenaires

Contacter le service commercial

Pour les États-Unis et le Canada

S'inscrire

Essais gratuits

Produits & Services

Apprendre

À propos d'Ansys

Back

Produits & Services

Back

Apprendre

Ansys donne les moyens à la prochaine génération d'ingénieurs

Les étudiants ont accès gratuitement à un logiciel de simulation de classe mondiale.

Back

À propos d'Ansys

Concevez votre avenir

Connectez-vous à Ansys pour découvrir comment la simulation peut alimenter votre prochaine percée.

Espace client

Support

Communautés partenaires

Contacter le service commercial

Pour les États-Unis et le Canada

S'inscrire

Essais gratuits

Racing is a perfect blend of precision, speed, and strategy. In recent years, technology has brought a seismic shift to the way cars are designed, analyzed, and optimized. Students around the globe are harnessing advanced simulation tools to explore complex engineering principles, turning what was once trial and error into data-driven innovation. These tools help young engineers push the boundaries of aerodynamics, materials science, and design, giving them an edge both on and off the track — particularly a miniature one.

STEM Racing (formerly F1 in Schools) is an innovative nonprofit program that pioneered miniature Formula One (F1) racing in 1999. Over the course of a year, students design, analyze, build, and race compressed-air-powered cars, gaining real-world skills in engineering, design, and project management. And with modern simulation tools reshaping how vehicles are developed, young competitors can now test ideas, refine aerodynamics, and optimize materials with precision once reserved for professional teams.

Team Lunar Finds Simulation-Fueled Success

STEM Racing 2025 World Finals participants

Fresh off its victory in Singapore, Team Lunar from Brighton Grammar School in Australia has cemented its place among the top teams in the STEM Racing world. The student team took the 2025 Aramco STEM Racing World Championship, along with awards for Best Engineered Car and Fastest Car. These achievements were built on years of dedication, teamwork, and technical growth. There’s no doubt that the team’s meticulous approach and collaboration across disciplines has made it a standout in the global competition.

Team Lunar wins the 2025 STEM Racing World Finals.

Lunar’s 2025 finals car

A major factor in Lunar’s success was the strategic use of simulation. With support from LEAP, an Ansys Elite Channel Partner, Lunar incorporated GPU-accelerated Ansys Discovery 3D product simulation software for aerodynamic testing and Ansys Mechanical structural finite element analysis (FEA) software for structural analysis. These accelerated tools enabled the team to evaluate even more design combinations, address new regulatory challenges, and test wheel strength, halo performance, and tether systems with confidence long before manufacturing began.

Lunar’s car in action at the 2025 world finals

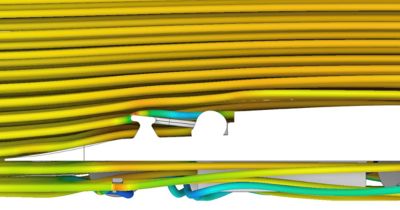

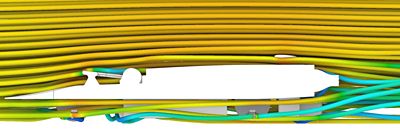

The use of accelerated Discovery software for computational fluid dynamics (CFD) analysis enabled the team to visualize airflow interactions and identify critical areas for aerodynamic improvement, such as the high-drag regions behind the front wheels. These insights guided adjustments to the front wing design, resulting in more streamlined airflow. By simulating airflow changes around the front wheels, the team refined its design early and reduced physical testing time by 86%, saving an estimated $9,000 AUD ($6,000 USD) — 14% of its budget — in development costs.

“Because of Ansys, we were able to test over 100 design combinations in the background while working on other project elements,” says Max Zylberman, engineering director for Team Lunar.

Cross-sectional streamlines analysis of Lunar’s 2025 STEM Racing World Finals car

The team used Mechanical software for FEA, which was crucial for ensuring the structural integrity of key components. By simulating load conditions and stress points, the team could confirm that its designs met all regulatory strength requirements before manufacturing. The combination of CFD and FEA provided Lunar with a comprehensive approach to optimizing both performance and compliance.

NVIDIA-accelerated simulation tools enabled the team to focus on refining top-performing designs, significantly reducing manufacturing time and costs. By improving workflows and empowering the team to focus on innovation, Ansys simulations became a cornerstone of the championship-winning strategy.

SBA Unity Racing Drives Innovation Through Simulation

The SBA Unity Racing team, national champions from Scarborough UTC in the United Kingdom, made its mark in the 2025 STEM Racing World Finals, securing third place on the global stage. Each team member brings unique skills to the table, but it's their shared determination and problem-solving mindset that have driven their success.

SBA Unity Racing has made advanced simulation tools an integral part of its car development process with help from an Ansys Student Team Partnership. Through the 2024-25 competition season, the team primarily relied on Discovery software and Ansys Fluent fluid simulation software to refine its designs. Jack Metcalfe, the design engineering team principal for SBA Unity Racing, explained how the team relied on both Fluent and Discovery software, each for different strengths in the design workflow. Fluent software provided deep, data-rich aerodynamic insights while Discovery software excelled at rapid concept development and mechanical testing — especially early in the process.

Fluent software enabled the team to dive deeper into the aerodynamic performance of the car, producing large volumes of data that guided design refinements. Discovery capabilities enabled the team to generate and analyze thousands of wheel variations automatically, helping it quickly identify the strongest, most manufacturable design.

“I can just set my computer running for a week, and it will automatically generate 2,000 different wheel designs … all graphed very nicely so I can see which wheel is optimal,” Metcalfe says.

Using Ansys, part of Synopsys, solutions provided significant advantages, from reducing development time to optimizing car performance. The team’s innovative use of parametric simulations in Discovery software helped identify an optimal wheel design, cutting its weight by more than half — from 1.1 grams to just 0.44 gram — while maintaining structural integrity. This weight reduction contributed directly to improving the car’s speed and efficiency.

The ability to test design iterations without physical prototypes saved countless hours and resources. These tools not only enhanced the team’s engineering capabilities but helped it maintain a competitive edge by enabling data-driven design decisions.

The success has also inspired an entire ecosystem in the school, with seven new teams looking to compete in the 2026 season, each motivated by Unity’s achievements.

Ansys Digital Twin Racetrack Powered by NVIDIA Omniverse

One of the most exciting developments in this year’s STEM Racing competition was the debut of the Ansys digital twin racetrack, powered by Discovery software and integrated NVIDIA Omniverse libraries. This virtual track delivers an incredibly accurate representation of real-world racing conditions, giving teams an interactive way to see how different preloaded parts perform. During the 2025 STEM Racing World Finals, students used a simplified workflow by swapping predesigned front and rear wings to observe how design adjustments impact car performance. As part of the 2025-2026 STEM Racing season, demo days will give participants access to a more advanced workflow, enabling them to upload custom designs for detailed CFD analysis and optimization in Discovery software.

A demonstration of the digital twin racetrack for STEM Racing, presented at the STEM Racing 2025 World Finals

The more advanced digital twin racetrack integrates car designs from Discovery software with NVIDIA Omniverse libraries, enabling real-time airflow visualization and enhanced understanding of aerodynamic concepts. Students can refine their miniature car designs, analyze CFD data, and observe how changes impact real-world performance. This setup provides an interactive learning environment, enabling students to explore advanced topics, such as aerodynamic drag and iterative design.

Unity Racing was invited to play a role in the development of the track, meeting multiple times to give feedback from early concept stages through user interface design, data outputs, and overall system usability.

“It’s fully integrated into how we approach car simulations. It’s one thing to model different front wings; examine drag, lift, and load distribution; and draw your own conclusions. But being able to know exactly how those factors will affect on-track behavior is something we don’t really get outside of this nuanced model,” says Metcalfe.

Members of the Unity Racing team, which collaborated with Ansys and its partners to create the digital twin track

Accelerating the Next Generation

Simulation has become far more than a competitive advantage in STEM Racing — it’s a catalyst for learning, creativity, and confidence. Whether teams are optimizing wheel structures, reshaping aerodynamic surfaces, or testing full race strategies on a digital twin track, these tools give students the freedom to experiment boldly and fail safely. The result is a new generation of young engineers who think analytically, collaborate effectively, and approach complex problems with curiosity and precision. By blending hands-on building with the power of advanced digital tools, STEM Racing turns miniature cars into meaningful engineering experiences and sets students on a fast track toward the innovations of tomorrow.

By merging passion with technology, the future of racing and STEM education is speeding toward uncharted opportunities.

Learn more about how an Ansys Student Team Partnership can enable your STEM Racing team to secure a podium finish.

Just for you. We have some additional resources you may enjoy.

“Because of Ansys, we were able to test over 100 design combinations in the background while working on other project elements.”

— Max Zylberman, engineering director, Team Lunar

The Advantage Blog

The Ansys Advantage blog, featuring contributions from Ansys and other technology experts, keeps you updated on how Ansys simulation is powering innovation that drives human advancement.