-

-

Accédez au logiciel étudiant gratuit

Ansys donne les moyens à la prochaine génération d'ingénieurs

Les étudiants ont accès gratuitement à un logiciel de simulation de classe mondiale.

-

Connectez-vous avec Ansys maintenant !

Concevez votre avenir

Connectez-vous à Ansys pour découvrir comment la simulation peut alimenter votre prochaine percée.

Pays et régions

Espace client

Support

Communautés partenaires

Contacter le service commercial

Pour les États-Unis et le Canada

S'inscrire

Essais gratuits

Produits & Services

Apprendre

À propos d'Ansys

Back

Produits & Services

Back

Apprendre

Ansys donne les moyens à la prochaine génération d'ingénieurs

Les étudiants ont accès gratuitement à un logiciel de simulation de classe mondiale.

Back

À propos d'Ansys

Concevez votre avenir

Connectez-vous à Ansys pour découvrir comment la simulation peut alimenter votre prochaine percée.

Espace client

Support

Communautés partenaires

Contacter le service commercial

Pour les États-Unis et le Canada

S'inscrire

Essais gratuits

Discover how Honeywell and Ansys are playing a transformative role in battery manufacturing.

As demands for novel battery technology grow, manufacturers find themselves challenged to balance the needs for higher energy density, faster charging, safer, more sustainable battery applications, and reducing costs.

Still, in the race to build a better battery, production ramp-up remains a challenge. Recent research suggests that 76% of manufacturers will need to upgrade or build new production lines now to support novel battery cell technology in the future. Such challenges require smart manufacturing solutions built on more scalable, digital foundations.

Those digital foundations mean manufacturers need to shift from traditional trial-and-error methods to data-driven, model-based approaches on the gigafactory floor (facilities designed to support mass production of electric batteries). The high cost of inefficient battery production creates a clear need for simulation-driven control solutions for Honeywell customers who prioritize activities around quality optimization and scrap reduction.

Honeywell Process Solutions helps organizations solve complex challenges in automation, process control, and quality management related to battery manufacturing. The company sees a connected future in high-volume battery production using simulation as the solution to overcoming the prohibitively high cost of entry for battery manufacturers into various markets, including electric vehicles (EVs), electronics, energy storage, and consumer goods.

Ansys Digital Twin software is a key enabler for a Honeywell gigafactory initiative that lays the groundwork for future expansions into battery production across industries.

“Digital engineering is the backbone of modern smart manufacturing,” says Fredrik Westerberg, director of strategic planning, gigafactories, at Honeywell. “By combining physics-based simulation with real-time data, we’re enabling self-optimizing production lines that adjust dynamically to changing conditions. In battery manufacturing, integrating Ansys’ simulation portfolio to create physics digital twins with Honeywell’s automation systems allows us to fine-tune processes in real time — leading to higher yield, lower costs, and improved energy efficiency.”

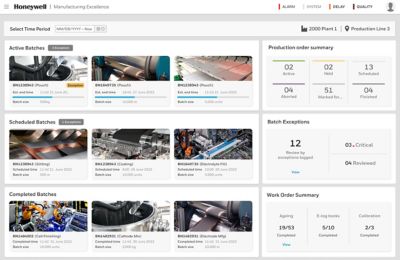

Optimized operation of gigafactories from day one with the Honeywell Battery Manufacturing Excellence Platform (MXP)

Honeywell Process Solutions Helps Manufacturers Scale Up to Something New

Battery manufacturers face numerous technical and operational issues when attempting to scale production. Factories that want to scale up to mirror existing gigafactories are often limited by a newly hired local workforce who may not understand the technology or the process. The copy-paste approach creates a bottleneck effect that puts a strain on production.

Then there are the specialty producers who’ve done cell design in the United States or Europe with novel technology they’ve tested in the lab. They’re often operating on a factor of 100 times smaller than a larger factory. They’ve run the qualifications on their cells and they have a customer. Now, through testing and validation, they need to take that experience and translate it into mass production.

Honeywell is playing an integral role in supporting these efforts. Its Battery Manufacturing Excellence Platform (Battery MXP) facilitates end-to-end visibility into the safety, efficiency, and quality of the entire gigafactory production process — insights crucial to driving efficiency. This AI-powered software solution is designed to optimize the operation of gigafactories from day one by improving battery cell yields and expediting facility startups for manufacturers.

“Our expertise begins with the precursors to battery manufacturing — from lithium mining to chemical processing, to the foils, films, and materials needed during production,” adds Westerberg. “It extends to the building of packs and modules, and the sensors responsible for monitoring battery safety during their operation in EVs and energy storage containers. And ultimately, the automation of the entire battery manufacturing process.”

A Smart Toolchain Built on Ansys Technology

The Honeywell platform was developed in consideration of customer goals to reduce and eliminate propagation of error through the process — for example, to optimize the control algorithm in the electrode calendering by a high-fidelity digital twin. The process controls gain the ability to understand and characterize complex relationships among multiple inputs (material properties, process behavior, controls, sensor information) and the required outputs necessary to maintaining optimal control of the manufacturing process.

In response, Honeywell created a simulation toolchain with Ansys technology using Ansys Rocky software, Ansys optiSLang software, Ansys Twin Builder software, and Ansys TwinAI software to build and deploy a physics-informed digital twin. This digital twin was then integrated into Honeywell’s latest control system to enable data inputs to be processed along with measurements from Honeywell sensors before sending commands to the manufacturing equipment.

Digitization of the entire process ensures that critical quality metrics, such as electrode density and thickness, are maintained within spec.

Processes such as calendaring, when modeled in Ansys simulation software, enable parameters like material thickness to be evaluated to improve Honeywell Controls' manufacturing process.

Intelligent Analysis Times Two

Ansys TwinAI software (an AI-augmented, simulation-based digital-twin application) enabled Honeywell to move from feedback to predictive process control. The integration of digital twins, which are integrated data-driven virtual representations of real-world entities and processes into its manufacturing solution delivers many benefits for Honeywell customers.

This technology facilitates the move in high-volume battery manufacturing from islands of automation to autonomous operations. It offers closed-loop control via in-line sensing attached to assets that can deliver real-time data, further optimizing production scale-up by improving quality. The speed of this information exchange helps manufacturers to identify root causes, ridding the process of defects and deviations before issues escalate as production ramps up.

Ansys Digital Twin technology has also shifted Honeywell’s approach to quality control from being a reactive exercise to a more predictive, proactive one. It enables virtual “what-if” scenarios before making any real-world adjustments to prevent costly mistakes. It also allows for the addition of parameters to increase model prediction fidelity and identify sensitivities to different inputs and their impact on the process.

“Our use of Ansys Digital Twin technology continues to make a significant impact on waste reduction during manufacturing,” says Westerberg. “Just a 1% loss in quality control can result in $1 million in scrap costs per GWh per year. Digital twins help minimize these losses.”

Scrapping Inefficiencies, Not Materials

Of course, designing and operating a manufacturing process, according to Westerberg, is not without challenges. The first centers on process variability and control. In high-volume manufacturing, detecting and accounting for the presence of small variations in material properties or process parameters is crucial. Through propagation of error these variations can lead to defects in finished cells, which may further lead to cell failures several months, or even years later in a customer application.

Second, there are automation and efficiency challenges. Trial-and-error adjustments of copy-paste manufacturing processes depends on operator experience and equipment provider expertise. These numerous adjustments can be time-consuming and costly when scaling up a production line. Within this open-loop system, there’s also a good deal of variability that can progress through existing quality gate points all along the production line resulting in scrap that must be accounted for.

Finally, it is important to capture the impact of quality and yield optimization on the bottom line. “Scrap costs in lithium-ion battery manufacturing can reach tens of millions of dollars per year and the cost of poor quality, for example a recall, can cost billions,” says Westerberg.

Simulation enables the predictive modeling necessary to help mitigate these and other risks impacting production.

“Our work with Ansys has helped us move beyond automation to closed-loop autonomous systems, reducing manual intervention and improving consistency,” says Westerberg. “By integrating Ansys simulation technology into real-time control systems, we ensure key quality metrics — like electrode thickness and density for a calendaring process, for example — are maintained, minimizing waste.”

Today, Ansys Twin Builder software is also helping manufacturers solve extremely large, complex safety challenges. Check out our recent blog “Safety First: How One Powerful Computational Combo Can Make All the Difference” to learn more.

Just for you. We have some additional resources you may enjoy.

“Our use of Ansys Digital Twin technology continues to make a significant impact on waste reduction during manufacturing. Just a 1% loss in quality control can result in $1 million in scrap costs per GWh per year. Digital twins help minimize these losses..”

— Fredrik Westerberg, director of strategic planning, gigafactories, Honeywell

The Advantage Blog

The Ansys Advantage blog, featuring contributions from Ansys and other technology experts, keeps you updated on how Ansys simulation is powering innovation that drives human advancement.