Case Study

-

-

Accédez au logiciel étudiant gratuit

Ansys donne les moyens à la prochaine génération d'ingénieurs

Les étudiants ont accès gratuitement à un logiciel de simulation de classe mondiale.

-

Connectez-vous avec Ansys maintenant !

Concevez votre avenir

Connectez-vous à Ansys pour découvrir comment la simulation peut alimenter votre prochaine percée.

Pays et régions

Espace client

Support

Communautés partenaires

Contacter le service commercial

Pour les États-Unis et le Canada

S'inscrire

Essais gratuits

Produits & Services

Apprendre

À propos d'Ansys

Back

Produits & Services

Back

Apprendre

Ansys donne les moyens à la prochaine génération d'ingénieurs

Les étudiants ont accès gratuitement à un logiciel de simulation de classe mondiale.

Back

À propos d'Ansys

Concevez votre avenir

Connectez-vous à Ansys pour découvrir comment la simulation peut alimenter votre prochaine percée.

Espace client

Support

Communautés partenaires

Contacter le service commercial

Pour les États-Unis et le Canada

S'inscrire

Essais gratuits

“Simulation is critical R&D infrastructure for Grundfos. It is one of the key components of our ability to be a market leader in efficiency, robustness, and sustainability. During the last 10 years of simulation adoption, we have scaled from a few specialists to hundreds of engineers adopting simulations, and thereby transformed how we conceptualize, design, and verify our products.”

— Anders Bøge Jensen

Head of Mechanical Module Technology, Grundfos

From Test-Driven to Simulation-Driven: Grundfos Democratizes Simulation and Automates Workflows to Boost Innovation, Sustainability, and Robustness

Grundfos, one of the world’s largest water pump manufacturers, has transformed its product development by embedding simulation at the core of its research and development (R&D) strategy. A simulation journey that began 10 years ago with a handful of specialists has grown into a global network of 300 users across four primary R&D sites and 10 different simulation disciplines, including 150 mechanical finite element analysis (FEA) users. This shift from test-driven to simulation-driven development enables faster innovation, higher efficiency, and greater product robustness.

Challenges

With thousands of product configurations and highly complex pump designs, Grundfos faced challenges in efficiently verifying performance and robustness. Relying heavily on physical testing slowed development, increased costs, and limited scalability. As sustainability targets and customer demands grew, Grundfos needed a way to accelerate design, reduce physical prototypes, and ensure product durability across an expanding product portfolio.

Engineering Solutions

During the last decade, Grundfos has integrated tools that democratize simulation, including the Ansys Workbench simulation integration platform, Ansys Mechanical FEA software, Ansys Discovery 3D product simulation software for conceptual design, and Ansys optiSLang process integration and design optimization software. EDRMedeso, an Ansys Elite Channel Partner, has provided training and support.

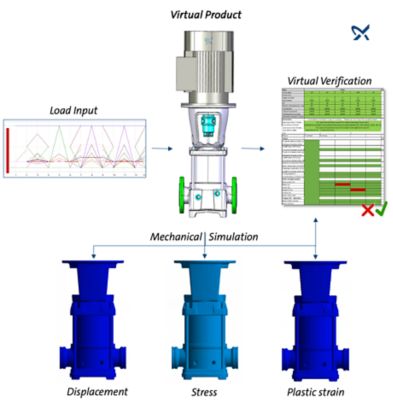

For example, Grundfos engineers developed what they call a “virtual product simulator” based on the Workbench platform, Microsoft Excel inputs, and integrations with Grundfos’ native computer-aided design (CAD) platform. Team members select the variant, and the application automatically configures correct loads and materials, running different load cases to verify structural robustness, including durability and static strength for a complete pump. It automates verification across thousands of pump variants, reducing manual effort and improving consistency.

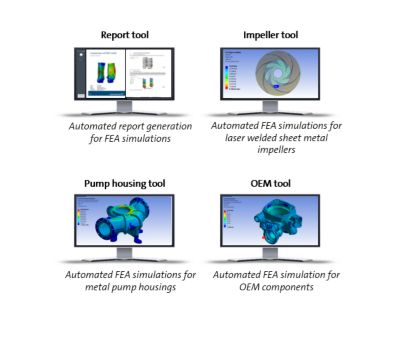

Other vertical apps created for FEA simulations include tools for reports, impellers, pump housing, and composite components. They also use Ansys HPC solutions for scalability.

Benefits

Grundfos ensures robust and efficient products with less reliance on physical testing by integrating simulation and workflow automation throughout their concept, design, and verification phases. They realized:

- Accelerated simulation workflow for select vertical apps, including up to an 85% reduction in simulation efforts and a 95% reduction in simulation lead time.

- Improved product reliability with lower warranty rates and fewer market failures

- Greater scalability with the ability to evaluate thousands of product configurations virtually

- Increased sustainability with fewer prototypes, reduced test energy consumption, and more energy-efficient pump designs

“We have one example where we can produce to stock maybe half a year earlier than if we didn’t use the simulations because we trust the simulation so much that we can build up the stock in advance, go to market earlier, and save money in that way,” says Brian Lundsted Poulsen, Chief Mechanical Simulation Specialist at Grundfos. “We can also cut down on some of the tests, which can be really expensive for these products and consume a lot of power. So, if we can just take out a few of these robustness tests, it will have a large impact on sustainability and operational R&D costs.”

Images and graphics

Grundfos built a “virtual product simulator” vertical app using the Ansys Workbench platform and Microsoft Excel inputs to automate verification across thousands of pump variants, which reduced manual effort and improved consistency.

Grundfos built additional vertical apps for finite element analysis (FEA) simulations, including a report tool, an impeller tool, a pump housing tool, and an original equipment manufacturer (OEM) tool.

Grundfos CR in-line multistage pumps are centrifugal pumps with suction and discharge ports on the same level. They are suitable for a wide range of applications, including but not limited to commercial heating, air conditioning, and water pressure boosting, as well as industrial heating, cooling, and water supply and transfer.

Grundfos ALPHA2 GO is a high-efficiency circulator pump designed for heating and air conditioning systems. It is suitable for commercial heating and air conditioning, district heating and cooling, and domestic heating and hot water recirculation.

Commençons

Si vous êtes confronté à des défis d'ingénierie, notre équipe est là pour vous aider. Forts de notre expérience et de notre engagement en faveur de l'innovation, nous vous invitons à nous contacter. Collaborons pour transformer vos obstacles techniques en opportunités de croissance et de réussite. Contactez-nous dès aujourd'hui pour entamer la conversation.