-

-

Accédez au logiciel étudiant gratuit

Ansys donne les moyens à la prochaine génération d'ingénieurs

Les étudiants ont accès gratuitement à un logiciel de simulation de classe mondiale.

-

Connectez-vous avec Ansys maintenant !

Concevez votre avenir

Connectez-vous à Ansys pour découvrir comment la simulation peut alimenter votre prochaine percée.

Pays et régions

Espace client

Support

Communautés partenaires

Contacter le service commercial

Pour les États-Unis et le Canada

S'inscrire

Essais gratuits

Produits & Services

Apprendre

À propos d'Ansys

Back

Produits & Services

Back

Apprendre

Ansys donne les moyens à la prochaine génération d'ingénieurs

Les étudiants ont accès gratuitement à un logiciel de simulation de classe mondiale.

Back

À propos d'Ansys

Concevez votre avenir

Connectez-vous à Ansys pour découvrir comment la simulation peut alimenter votre prochaine percée.

Espace client

Support

Communautés partenaires

Contacter le service commercial

Pour les États-Unis et le Canada

S'inscrire

Essais gratuits

ANSYS BLOG

June 24, 2019

HyperXite Accelerates Hyperloop Pod Design with Ansys Discovery

HyperXite is pursuing a singular mission: to accelerate the design of future transportation. Since 2015, the University of California, Irvine (UCI) student team has been developing pods — high-speed capsules designed to travel in near-vacuum tubes called hyperloops.

Students working on the HyperXite Pod IV using ANSYS Discovery Live.

This technology, as envisioned by Elon Musk, will support a sustainable transit system capable of rocketing commuters from Los Angeles to San Francisco in 30 minutes.

To excel in Musk’s SpaceX Hyperloop Pod Competition, HyperXite must satisfy an ever-increasing need for speed. Each year, entrants successfully raise the speed bar — prompting SpaceX, this year, to make speed the sole judging criterion.

The speed to beat in 2019 is 290 mph (700 mph is the ultimate target).

The Need for Design Speed in the Hyperloop Pod Competition

But it's not just about how fast the pod travels. Speed is also essential in the pod development process.

Watch the HyperXite team use Discovery Live to optimize their pod designs.

HyperXite begins researching its new pod each fall. Within a nine-month window, it will have to meet a series of deadlines, satisfy safety standards, secure a spot in the finals and complete construction.

And, for four years now, the UCI engineering team has been gaining ground. It has successfully accelerated both pod speed and design time.

Jason Lee, team captain and chief engineer, credits much of this forward motion to Ansys Discovery Live simulation.

"The pressure is on for us. We're trying to outdesign teams from around the world and bring a brand-new pod to the table in less than a year," says Lee. "For the 2019 competition, we began using Discovery in the concept stage. It completely transformed our ability to collaborate and innovate.”

Simulation-Enabled Collaboration Cuts Design Rework

When HyperXite began work on its first pod in 2015, only a few team members were experienced with simulation model setup, geometry meshing and results validation.

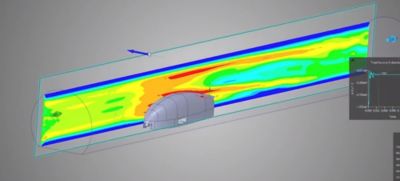

Instant computational fluid dynamics (CFD) simulation created using ANSYS Discovery Live

The design engineers would hand off their CAD files to the simulation experts. They would run the simulations and return the results to the designers for further refinement — or a complete do-over. The process would then repeat.

According to Lee, this back-and-forth took between four and five months and innovation was often lost in translation.

"We had designers who weren't trained as structural engineers, so the two groups were limited in their ability to communicate effectively," says Lee. "Discovery puts the power of simulation in our designers' hands. It provides a platform for collaboration between our design and simulation teams.”

HyperXite's designers were able to start simulating with Discovery almost immediately — with minimal training. They could quickly run through many design iterations, making decisions and revisions with real-time feedback all along the way. By catching flaws early, the design team was able to eliminate or correct bad designs before passing them off for more in-depth structural analyses.

"With Discovery on our team, we no longer have a disconnect between our designers and our simulation experts,” says Lee. “They can work together and tweak a design to improve our downstream results. We've significantly reduced our development time — it’s now one month instead of five."

Off to the Races with an 80% Lighter Hyperloop Pod

The product of HyperXite’s new simulation workflow is the Pod IV. It is faster and 80% lighter than the team’s 2018 model. The carbon-fiber pod features an electric motor, drive wheel, pressure vessel, cooling reservoir and customized magnetic braking system.

HyperXite undergraduate team from the University of California, Irvine.

In July, HyperXite will compete in the finals against 24 other teams. The top three will have the opportunity to race their pods inside the 1-mile Hyperloop tube.

“Win or lose, I think we all feel that we’re contributing to a less congested, less fuel-dependent future,” says Lee. “All of the research and designing we’ve done, all of the prototypes we’ve built, are moving us closer to next-generation transportation systems.”

To learn more about accelerating a 3D design workflow, begin a trial of Ansys Discovery Live.

Or, learn how your team can apply for an Ansys student team sponsorship.