-

-

Accédez au logiciel étudiant gratuit

Ansys donne les moyens à la prochaine génération d'ingénieurs

Les étudiants ont accès gratuitement à un logiciel de simulation de classe mondiale.

-

Connectez-vous avec Ansys maintenant !

Concevez votre avenir

Connectez-vous à Ansys pour découvrir comment la simulation peut alimenter votre prochaine percée.

Pays et régions

Espace client

Support

Communautés partenaires

Contacter le service commercial

Pour les États-Unis et le Canada

S'inscrire

Essais gratuits

Produits & Services

Apprendre

À propos d'Ansys

Back

Produits & Services

Back

Apprendre

Ansys donne les moyens à la prochaine génération d'ingénieurs

Les étudiants ont accès gratuitement à un logiciel de simulation de classe mondiale.

Back

À propos d'Ansys

Concevez votre avenir

Connectez-vous à Ansys pour découvrir comment la simulation peut alimenter votre prochaine percée.

Espace client

Support

Communautés partenaires

Contacter le service commercial

Pour les États-Unis et le Canada

S'inscrire

Essais gratuits

ANSYS BLOG

January 15, 2020

How to Assess and Prevent High-Cycle Fatigue Failure

People often think that structural failures are the result of dramatic events — like the aftermath of collisions or overloaded equipment. But there are plenty of ways for things to break.

For instance, fatigue failure is defined as a structural breakdown that occurs due to repetitive cycles of stress. To prevent these events, and extend the life of their products, engineers need to understand a design’s durability. Otherwise, they risk developing products that are overdesigned or break before warranty.

Fatigue failure studies how cracks created from repeated use can grow until the material breaks.

Repetitive loading cycles don’t have to be dramatic. They are generally a part of a product’s typical daily routine. But, over time, these cycles can cause microcracks within the material. Sometimes the cracks remain unchanged, sometimes they grow. If the cracks grow, eventually they can become large enough to cause catastrophic failure.

Some might refer to this phenomenon as material fatigue, but that is a more generalized problem that expands into mechanisms like the delamination or fiber breakage of composites. Traditional fatigue failure only looks at the growth of cracks in materials like metals.

The History of Fatigue

Machine component fatigue was recognized at the onset of the industrial age. Engineers started to notice that some parts would fail when similar ones wouldn’t.

These early engineers discovered that repetitive loads were the cause. Through physical testing of components, they were able to produce stress-life curves (S-N curves) similar to ones currently in use.

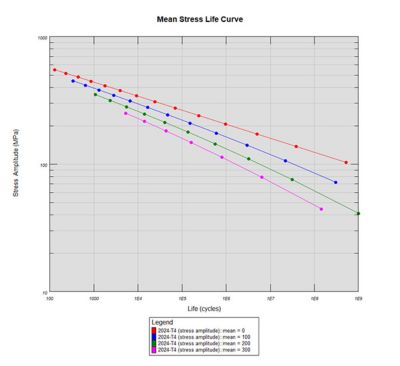

An S-N curve

However, the actual mechanism of these failures was still unknown. Decades would pass before it was recognized that each load cycle consumed a portion of the component’s life. This information could be used to estimate the number of loads until failure.

As a result, parts were overdesigned to handle large loads that were shown never to cause fatigue failures. In other words, product durability was traditionally solved by limiting the components’ stress levels. This translates into larger, heavier parts that are associated with little innovation, high carbon footprints and material waste.

Current consumers want better, lighter, greener products. Therefore, the goal is to assess the durability of a design so that engineers can meet warranty requirements, weight, material usage, carbon footprints and more.

How to Design for Fatigue

An S-N curve is used to assess the number of cycles a design can survive based on stress levels. Originally, these curves were created by cyclically loading the actual components. Over time, they were made by cyclically loading material specimens.

These curves haven’t changed much in the last 150 years. What has changed is how engineers can use them to design against fatigue failures.

Low-cycle problems deal with metal plasticity. These require a different solution than fatigue failure.

Currently, engineers can record the actual load history a component will experience. They also have the compute power to calculate all the stress cycles and damage that load history would cause.

Instead of designing the component to survive the maximum stress cycle for its design life, engineers can design it to survive the accumulated damage from all the actual stress cycles in its history.

Fatigue can be classified as high-cycle or low-cycle. When a load can be applied to parts thousands or millions of times before failure, that is considered high-cycle. These loads create stress levels well below those required for a static strength failure. Simple linear elastic analyses can be used to predict the damage.

Low-cycle problems, however, deal with high loads and metal plasticity. This is solved and studied differently than high-cycle fatigue as plastic deformations require the use of nonlinear stress analyses.

Both regimes, however, can be solved with the appropriate S-N curve and cycle-by-cycle damage calculations.

The Challenges to Design for Fatigue

One of the biggest challenges in predicting fatigue failure is characterizing the load over a part’s lifetime.

This can be done by adding sensors that measure vibrations, stress and other loads of interest. These loads can then be added to the finite element analyses (FEAs) of future models.

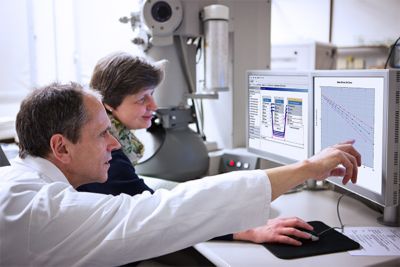

Engineers can assess an S-N curve, or stress-life curve.

Studying the effects of these loads will require complex simulations run with a lot of computing power because those sensors will generate a lot of data.

The Benefits of Fatigue Analysis

Studying fatigue failure enables engineers to set meaningful design targets. For instance, if a bike frame is designed to last 10 years, engineers can determine the stress cycles over that time and assess whether their design would last.

Engineers will also be able to give the proper amount of attention to safety-critical components.

A latch that holds a cabinet door doesn’t require the same level of safety as a latch that holds a car door. An engineer designing that cabinet might be comfortable with failure rate of 0.2% while the automotive engineer will have to follow strict company and government regulations that dictate the failure rate. Either way, the analysis will ensure that these parts will have an appropriate service life.

This means that engineers can now predict a product’s life before they commit to validation and prototyping. This can help to improve designs early in development cycles, reduce budgets and spur innovation.

With modern load sampling devices, engineers can better assess the conditions experienced by their designs. As a result, fatigue analysis can help engineers design products based on the loads they will actually experience on a daily basis. This doesn’t just improve their high-cycle assessments, but any other structural assessment that has been done using load assumptions that do not reflect a product’s actual duty cycle.

How Simulations Affect Fatigue Testing

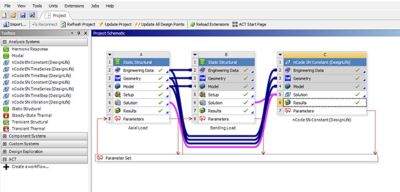

Engineers no longer have the time or budgets to tests a car’s duty cycle over hundreds of thousands of miles. Instead, they can use tools like Ansys Mechanical and Ansys nCode DesignLife.

Engineers can access ANSYS DesignLife within ANSYS Workbench

These tools enable engineers to ensure their products meet fatigue specifications by running numerous variations of the loads and designs until they are confident that it will survive past warranty.

For instance, they will be able to tell if that additional flange, drill hole, stamp or any other detail in the design will help or hinder the product’s life.

Better yet, these simulations and optimizations can be performed before the product is built, ensuring that design improvements are made early in the development cycle. Optimization algorithms can even be used to streamline this design processes.

To learn more, visit the product page for Ansys nCode DesignLife.