-

-

Access Free Student Software

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

-

Connect with Ansys Now!

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Countries & Regions

Free Trials

Products & Services

Learn

About

Back

Products & Services

Back

Learn

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

Back

About

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Free Trials

ANSYS BLOG

May 23, 2022

NI and Ansys Help Develop Faster and Safer ADAS Technology

Essential ingredients of any rewarding relationship include trust, safety, and security, whether it’s the relationships we have with family and friends or the connections we have with our favorite foods, phones, and computers. Naturally, this intimacy extends to the cars we drive — and, more reluctantly — the cars we don’t drive.

As autonomy continues to transform the automotive and transportation industry, it becomes even more necessary to establish greater feelings of trust, safety, and security in advanced driver-assistance systems (ADAS) and autonomous vehicles (AV) backed by verifiable data and solutions.

Historically, this burden of proof has fallen on ADAS and AV manufacturers and suppliers. It has been their responsibility to link together disconnected solutions throughout development, modify internal workflows, validate products, and ultimately increase confidence with consumers.

Today, Ansys and NI are taking the wheel to lessen their load through a strategic partnership that enables implementing a model-based systems engineering (MBSE) approach throughout the product life cycle — from design and development through operation. This effort seeks to enhance credibility and ensure confidence by pairing NI’s automated test and measurement systems technology with Ansys’ electronics, AV, and optical simulation software. It is of the utmost importance to connect simulations to physical hardware; without this connection, true verification and validation of systems cannot take place.

Automated Testing and Simulation: A Winning Pair

For the past 40 years, NI has reassured customers across multiple industries by supplying engineers with a modern approach to test data and analytics to unlock the full value of tests. Equipping companies with the hardware and connected workflows to enable teams to improve their performance by testing faster and designing better. For the past 50 years, Ansys has accomplished the same with simulation software.

Now the pair are steering innovation miles ahead for future decades together by bridging hardware and simulation to create connected solutions and a smoother ride for ADAS and AV customers.

Building on a longstanding relationship, the companies collaborated in early 2020 to explore potential solutions in autonomy to alleviate pain points for customers and close technology gaps throughout development.

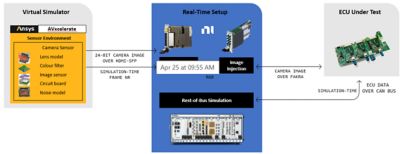

“There’s simulation, there’s real-world physical testing, and there’s a bridge in the middle — hardware-in-the-loop (HIL) testing — which combines simulation with real-world systems,” says Ashish Naik, Global Business Development Director of ADAS and AV at NI. “The goal of the Ansys and NI partnership is to essentially reduce the barrier and the obstacles for the customer to combine the best of both worlds from the best of both organizations.”

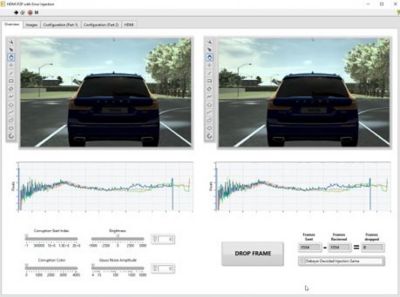

To do this, the teams developed a closed-loop solution for cameras that allows customers to inject raw simulation data directly onto NI hardware camera interface boards for faster verifiable results.

With Ansys AVxcelerate Sensors simulation software, you can generate a subset of images in real-time. As another option, you can integrate Ansys Speos to simulate advanced optical phenomena in a few seconds. Either software solution enables you to produce validated camera images in a fraction of the time it typically takes.

But the most helpful part and connection — or loop — to the physical world is that you can now inject this data directly onto NI hardware, essentially placing your sensors on actual vehicles to further test and validate your equipment.

Through this closed-loop solution, customers can visualize, analyze, and verify how their virtual prototypes interact with hardware and real-time systems. This capability amplifies the testing environment and interface to include the full operating system, application stack, and hardware. It can be expanded to replay test to compare and contrast simulation data with recorded real word data by testing perception algorithms and exercise the ADAS electronic control unit (ECU) fully.

In addition to cameras, Ansys and NI are developing similar closed-loop solutions for other sensors in the ADAS and AV space, including radar and lidar technologies.

Virtual Solutions to Better Your Autonomous Products — and Teams

Most of us recognize the benefits of virtual prototypes, but in ADAS and AV development, the digital variant goes beyond just advantageous — it’s critical.

To physically drive and test all variables, scenarios, or situations to ensure safety and functionality in the autonomous motor vehicle space is impractical. The millions of miles it would require would not only be unrealistic, but also timely, costly, and dangerous. Alternatively, simulation allows for a near-limitless number of test conditions without physical risk while drastically reducing physical labor and time.

And safety validation is a top priority at NI, with fault injection encouraged during testing to assess how autonomous systems react in complex, unexpected, and challenging situations. Likewise, it is a primary goal to reduce the number of defects and errors seen in ADAS and AV.

But a virtual environment doesn’t just create a safe space for repeatable, real-time testing; it also influences a positive impact on your team. With an open environment and workflow, team members collaborate and interact more directly, which helps break down silos.

Additionally, autonomy has shifted the course of automotive development. For standard vehicles, development was traditionally a predictable linear path from design and validation to verification and release.

Today, autonomous systems demand more agility and iteration. By reducing barriers and crystallizing teams, NI and Ansys can provide closed-loop solutions with built-in iterative workflows that meet these demands and inspire collaboration.

Still, it must be considered that the closed-loop test is only one piece of the complete ADAS software workflow. With NI's approach of one platform for record, replay and closed-loop HIL integrated into an open, data- and software-connected workflow powered by an ecosystem of subject matter experts, such as Ansys, you can test for performance and bring new and safer functions to market faster.

Plus, More Down the Road

With complementary portfolios, the Ansys and NI partnership will support additional crossover collaborations in the future, including electrification in transportation and digital twin technology for safety systems in aerospace and defense.

Further, the partnership will leverage cloud computing made possible through Microsoft and Ansys’ partnership via the Azure platform. This offers customers a unique opportunity to run accelerated computation purely in a simulated, or software-in-the-loop (SIL), environment within the cloud while simultaneously ensuring real-time performance within NI’s HIL systems.

“The Ansys and NI partnership is driven through real technology integration that we’re bringing together to solve real customer problems today,” says Naik. “This is our foundational core.”

To learn more about the current closed-loop solution for camera sensors, register for on-demand access to the webinar How Ansys and NI Came Together to Solve ADAS/AD HIL Validation.