-

-

Access Free Student Software

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

-

Connect with Ansys Now!

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Countries & Regions

Free Trials

Products & Services

Learn

About

Back

Products & Services

Back

Learn

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

Back

About

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Free Trials

TECNALIA used the Ansys Granta MI platform to move away from siloed projects toward structured data products, taking a practical approach to digitalizing materials research and development (R&D) and unlocking new opportunities to provide value to their clients.

Materials are the key to a sustainable future. From building materials to those used in IT technologies, energy, and other industries, the development of innovative materials has enabled our civilization to advance technologically at a rapid pace. Understanding, characterizing, and developing a material requires capturing the essence of how it receives its properties. This information must be captured, structured, and leveraged effectively to support the development of the next generation of materials.

For TECNALIA, Spain’s largest applied research and technology development center, materials are central to delivering on its mission: transforming technological research into prosperity by driving innovation in energy transition, construction, manufacturing, mobility, and digital technologies.

Across decades and through thousands of projects serving the public and private sector, Tecnalia faces the challenge of turning fragmented, project-based data into a knowledge base and strategic asset.

Unifying Data Silos

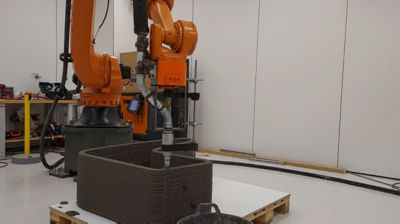

TECNALIA has worked with thousands of companies across sectors and industries, helping them understand and improve materials and their usage in an effort to build better, more durable, and more sustainable products. The company's expertise spans a wide range of materials and uses. TECNALIA has helped companies develop cement-based materials that support more sustainable construction and 3D printing applications; characterize metals under extreme conditions and develop preventive surface treatments; and create composites and resins with greater sustainability characteristics.

A construction component manufactured using 3D-printed cement mortar

Each project TECNALIA delivers generates a wealth of experimental data, including physical, chemical, and functional characterizations; performance tests; and application-specific evaluations. However, this project-based approach creates isolated data silos where data is stored locally, lacking any traceability, version control, or centralized data management. “Every client project had its own digital folder, its own restricted access,” says José Antonio Chica-Páez, the digital transformation leader at Energy, Climate and Urban Transition business unit of TECNALIA. “This guarantees confidentiality, but it makes it almost impossible to reuse knowledge across projects.”

Not only this, but as materials have evolved in capabilities and complexity, so has the heterogeneity and volume of data captured during a project, further compounding the digitalization challenge and leading to negative consequences such as repetitive testing and complicated data analysis. One of the most significant hurdles was the presence of legacy lab equipment — with some running on outdated operating systems — which made direct digital integration nearly impossible. Instead of replacing these machines, TECNALIA developed workflows to decouple data acquisition from equipment upgrades, enabling digitalization without disrupting existing infrastructure.

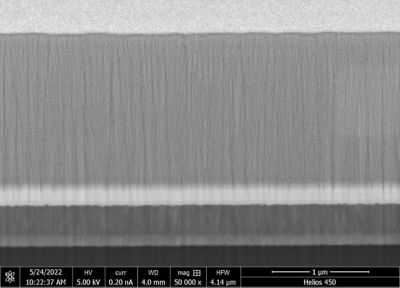

Advanced surface engineering processes to enhance material resistance, protection, and functionality

Building Data Products, Not Just Repositories

TECNALIA needed to rethink its data strategy and would not compromise for a simple solution, such as creating a massive data repository. Instead, the team embraced a more ambitious concept: data products.

“A data product is not just a collection of numbers,” says Chica-Páez. “It’s a structured set of variables — i.e., domain-based template, data, and metadata — that systematically provide evidence and insight into a specific outcome.” To ensure reusability and rapid adoption, researchers began building data products using familiar tools such as Microsoft's Excel and Access software. This approach enabled principal investigators to curate trustworthy, structured datasets without needing specialized software skills, lowering the barrier to entry and accelerating the cultural shift toward data-driven experimentation.

There are multiple value streams from thinking in terms of data products. Consolidated materials information, rapid access to a rich source of data, real-time updates for all stakeholders, connected information between projects, and compliance and quality control are some of these benefits.

The strategic value of data products comes from what can be offered as deliverables to clients versus what is delivered in today’s project. At a project’s conclusion, teams typically provide reports and test results of the experimental procedures used to characterize and evaluate a material or product. This approach offers the results that the client is looking for, but it does not provide insight into improving product performance or possible development strategies. With the data product approach, raw data is converted into a rich knowledge base of experimental evidence, providing possible development directions and insights that companies can explore to improve their products’ performance.

This shift toward data products is not just technical — it’s cultural. By enabling researchers to define and own their data structures, TECNALIA fosters a mindset in which data is seen not just as a byproduct of experimentation, but as a strategic asset that drives innovation.

Powering a Centralized Knowledge Base

For this strategy to be effective, choosing the right platform is critical. The platform not only needs to host these data products, but it also needs to manage crucial aspects such as traceability, heterogeneous data streams with rich metadata, IP protection, quality control, and access and version control. TECNALIA chose the Ansys Granta MI materials information management platform as this centralized source of information, because they “wanted a partner that speaks the language of the engineering world, and Ansys and Granta MI platform come from that world,” says Chica-Páez.

The Granta MI platform makes the data product concept work easily out of the box. “The principal investigator can create their own data product in a straightforward way — use the Granta MI platform to curate the data — in a validated manner. This gives us a guarantee that we can reuse the data in the future and constitutes a huge competitive advantage. In addition, we have adopted a local, or on-premises, storage solution based on TECNALIA servers. This guarantees total control of the databases, from intellectual property protection to administration and access control,” says Chica-Páez.

Interoperability with other business systems and software was also crucial, as was the ability to extract information programmatically with Python for advanced analysis. This capability is one of the strengths of the Granta MI platform. In the future, the idea is to also connect the Granta MI platform to TECNALIA’s simulation tools to further leverage their materials information in the development of new materials and the virtual evaluation of products, as well as encourage researchers to perform analyses directly with the Granta MI platform.

Cross-sectional scanning electron microscopy (SEM) view of a physical vapor deposition (PVD) coating designed to enhance wear resistance and corrosion protection

The Ansys engineering team helped TECNALIA identify their business needs and develop real use cases to bring immediate benefits for the company. This collaborative approach quickly identified the most impactful use cases to focus on, proved the solution’s value early on, and set the basis for the digitalization of data in other departments and business units.

A key success factor in developing workflows based on specific use cases was usability. Researchers can continue to work in the same way as before while using familiar tools, which reduces the barriers to adoption and fosters a culture of data-driven innovation.

Real-World Impact: Efficiency, Insights, and Value Delivery

The introduction of the Granta MI platform has already brought TECNALIA multiple benefits, including efficiency, data confidence, a faster path to insight, and strategic value.

With Granta MI software, TECNALIA can capture and analyze data faster and more reliably without upgrading legacy machines or changing the established workflows of their researchers. This leads to data traceability and faster adoption.

You can generate insights faster with built-in tools for visualization and filtering while also providing a programmatic option with Python to extract and analyze data, leveraging Python’s established data ecosystem. The data is connected, widely accessible across the organization, and can be used to support future programs with increased confidence.

By embracing the data product concept, TECNALIA wants to improve their services to go from simply delivering a pass/fail evaluation to providing clients with a trajectory — an evidence-based strategy for improving product performance. This evolution transforms the value proposition from reactive testing to proactive innovation guidance.

Make the Most of Your Materials Data

For TECNALIA, the Granta MI platform is becoming more than a software solution — it’s a strategic partner in digital transformation. As Chica-Páez says: “The Granta MI platform is a great partner for tackling a digital transformation project to manage data generated within infrastructure and labs. It also establishes the base to find new ways to leverage data in materials engineering, allowing us to offer our clients not only an evaluation but a trajectory for improvement.”

Looking ahead, TECNALIA envisions offering clients direct access to curated data products through the Granta MI platform, enabling them to explore insights, track performance trends, and even contribute their own data for collaborative innovation.

Learn more about how the Granta MI platform can help you leverage your data to unlock strategic value for your organization.

Just for you. We have some additional resources you may enjoy.

“The Granta MI platform is a great partner for tackling a digital transformation project to manage data generated within infrastructure and labs. It also establishes the base to find new ways to leverage data in materials engineering, allowing us to offer our clients not only an evaluation but a trajectory for improvement.”

— José Antonio Chica-Páez, digital transformation leader at Energy, Climate and Urban Transition business unit of Tecnalia

The Advantage Blog

The Ansys Advantage blog, featuring contributions from Ansys and other technology experts, keeps you updated on how Ansys simulation is powering innovation that drives human advancement.