-

-

Access Free Student Software

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

-

Connect with Ansys Now!

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Countries & Regions

Free Trials

Products & Services

Learn

About

Back

Products & Services

Back

Learn

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

Back

About

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Free Trials

ANSYS BLOG

January 10, 2023

Ansys Adds Rocky DEM to the Mix, Extending and Enhancing Multiphysics Simulation to Include Particle Dynamics

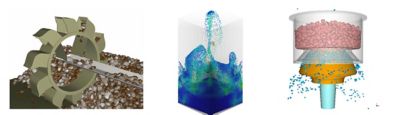

What do rocks, candy, and pharmaceuticals tablets all have in common? First, they are discrete solids, second their dynamic behavior and interactions are simulated with Rocky DEM. Imagine the complexity required to understand product quality, operational efficiency, and equipment performance associated with motion of particles of any shape needed for design of engineered mechanical systems. Imagine the insights needed to predict interaction of thousands or millions of particles as they bounce into one another and move through machines that mix, separate, sort, crush, disperse, and transport them. Picture biomass, gravels, and bulk material being moved by conveyors and augers, seeds being mechanically spread over a field, tablets and pills being coated, snacks transported for uniform packaging, debris being vacuumed up, or powders being mixed and compacted. All of these applications and more are simulated with Rocky DEM.

Discrete element method (DEM) is a computational modeling framework used to simulate the behavior of granular and discontinuous/non-uniform particles. Rocky is a leading DEM software package that combines the processing power of several graphical processing unit (GPU) cards to accelerate your particle dynamics simulations, enabling you to work with higher volumes of data in less time.

As proof to the point, Oracle Cloud Infrastructure (OCI) and NVIDIA recently performed a first-of-its-kind simulation of a 200-million particle analysis using Ansys Rocky DEM software on OCI’s bare-metal graphical processing unit (GPU) shape. Learn all about Rocky’s parallel load balancing algorithm that enables more efficient GPU resource utilization.

Mixing it Up with Particles, Fluids, and Structures

With the acquisition of Engineering Simulation and Scientific Software Rocky DEM, S.L., which was operated by long-time South American channel partner Engineering Simulation and Scientific Software (ESSS), Ansys adds Rocky DEM to its portfolio. Rocky has been offered by Ansys for almost two years as Ansys Rocky, a partner product, and is already integrated with Ansys flagship software. However, this acquisition will drive even deeper integration. For example, incorporating Rocky into the Ansys portfolio will also facilitate long-term synergies in the Ansys technology portfolio that would not otherwise be possible, such as inclusion of Rocky into the PyAnsys framework.

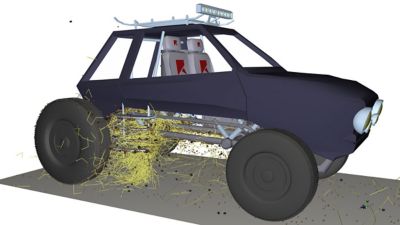

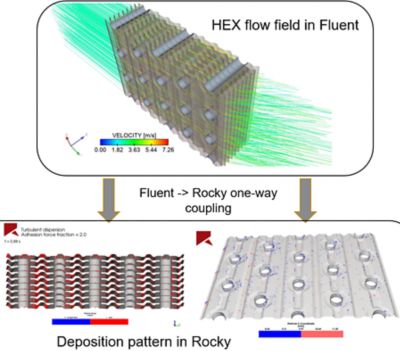

Rocky’s current integration into the Ansys Workbench environment enables coupling with Ansys Fluent and Ansys Mechanical for computational fluid dynamics (CFD) and finite elements analysis (FEA) simulations, respectively. The Fluent coupling enables you to perform multiphysics modeling to simulate how fluids affect the particle flow, and/or how the particles then affect the flow of the fluid. Rocky DEM can be coupled with Mechanical to model breakage or simulate how structural stresses are affected by the motion of multibody dynamics. Rocky also couples with Ansys Motion, which, when combined with CFD and/or FEA coupling, allows for flexible and comprehensive simulation of full mechanical systems involving bulk material movement.

The integration enables you to simulate phenomena like beans being ground in a coffee grinder, chocolate being coated with candy shells, rain drops adhering to windshields, a snowmobile navigating fresh powder, or the potential for dust and linnet to affect appliances. For example, Sub-Zero used Rocky to define and represent relevant airborne materials to model how they affect a refrigerator’s heat exchanger efficiency. Rocky has built-in capabilities to realistically model fibrous materials using a sphero-cylinder element joined by virtual bonds.

Ansys Fluent velocity simulation results of a heat exchanger. Bottom: particle deposition as predicted by Ansys Rocky.

Rocky also couples with Ansys Maxwell and Ansys EMA3D Charge to study charged particles subject to electromagnetic (EM) fields. The magnetic fields calculated by EM solvers are imported as point clouds into Rocky.

Existing integrations also enable you to perform design optimization analysis via Ansys optiSLang process integration and design optimization software.

A World of Possibilities

From fields to factories, from mines to pharmaceutical and medical labs, the opportunities for Ansys Rocky seem nearly endless. We are looking forward to working more closely with the Rocky team to expand particle dynamics applications beyond the traditional scope of DEM.