-

-

Access Free Student Software

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

-

Connect with Ansys Now!

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Countries & Regions

Free Trials

Products & Services

Learn

About

Back

Products & Services

Back

Learn

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

Back

About

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Free Trials

TOPIC DETAILS

What is Topology Optimization?

Topology optimization (TO or TopOpt) is a methodology for determining an object's optimal design to achieve a specific goal, given a set of constraints, loads, and boundary conditions, by adding or removing geometric features and adjusting their size.

Unlike traditional shape optimization, which only changes the size of a predefined topology, topology optimization uses algorithms to add and remove material within a specified design space to meet performance goals. These include minimizing mass, maintaining a temperature range, avoiding certain resonant frequencies, or keeping stress and deformation within allowable limits. By using the topology optimization method, engineers let an object’s performance determine its optimal material layout.

Topology optimization was initially limited to research and development (R&D) because the resulting geometries could not be manufactured using traditional manufacturing methods. However, additive manufacturing — and especially metal 3D printing — gives designers a way to produce the organic shapes generated by topology optimization. The introduction of manufacturing constraints into topology optimization tools controls the geometry so companies can manufacture their products with standard manufacturing techniques such as casting, molding, and forming.

Two other technical advancements have enabled more companies to integrate topology optimization into their design process.

The first involved coupling topology optimization algorithms with multiphysics simulation tools like Ansys Mechanical software or Ansys LS-DYNA software. This enabled engineers to move beyond simple structural optimization and include heat, acoustics, fluid flow, and even electromagnetics into their optimization.

The second advancement is the ability to easily convert the resulting topology back into a valid solid model. In the past, the topology optimization method created a faceted representation that required expert users to create a valid model in computer-aided design (CAD) software using the TopOpt output as a guide. Newer tools like Ansys Discovery software automatically fit and smooth the optimized surface once the iterations have converged on a final design.

Combined with a growing number of optimization formulations and increasing computational speed, these improvements have moved topology optimization into the mainstream of product design.

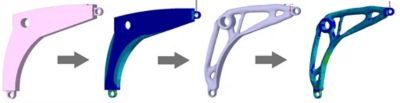

The steps in topological optimization used to reduce the weight of a bellcrank. From left to right: The original geometry, the stress profile of the original geometry, the topologically optimized geometry, and the stress profile of the topologically optimized geometry.

How Topology Optimization Works

The best way to visualize topology optimization is to look at the simplest form of TopOpt, binary structural optimization. Imagine a solid mass that fills the design space to be optimized. The engineer creates an FEA model representing the initial solid geometry and then defines how the object is held, what forces are applied, which material properties it contains, and the maximum allowable stress. The FEA software then discretizes the design space and solves for the unknown values.

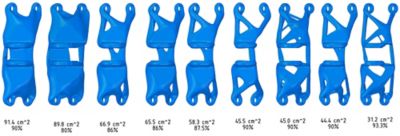

An example of multiple steps in a structural topology optimization of a bracket

Once the model solves and produces a result, the optimization algorithm in a topology optimization tool evaluates each element within the FEA model to see if it experiences loading. If an element does not, the algorithm removes it. The stiffness and density of each element are treated as binary variables because the element’s mechanical properties either contribute fully to the structural stiffness and mass or not at all. This approach simplifies and accelerates the optimization process by simply turning elements on or off rather than calculating an intermediate value.

This process repeats over subsequent iterations until the minimum mass is achieved while keeping the maximum stress below the allowable value. The resulting model is coarse and chunky, resembling a Lego model. To make it manufacturable, the engineer uses the resulting shape as a guide to create a refined CAD model. This process can be simplified with features like AutoSkin and SubD in Discovery software. This final model is used to create a verification FEA model to ensure the final material distribution meets design requirements.

All topology optimization is a variation of this basic structural analysis approach, with added complexity to the loads, physics, and goals.

6 Variations of Topology Optimization

The following variations increase the breadth of applications and improve the accuracy of the resulting geometry.

1. Continuous Variables

In its simplest form, the topology optimization method involves adding or removing elements in the design domain. When the discretization is fairly coarse, the resulting topology can be blocky and difficult to convert into smooth surfaces. Binary variables also introduce numerical instability into the simulation. To solve these problems, more advanced topology optimization techniques use continuous variables for characteristics like stiffness, thermal conductivity, or density.

2. Multivariable Objective Functions

Topology optimization algorithms iteratively modify variables in the design space to achieve a goal, known as an objective function. In many cases, there is only one objective function: mass. However, in the real world, engineering usually involves several, often contradictory, goals. Advanced topology optimization software can handle multiple goals simultaneously using multivariable objective functions and more complex mathematical methods.

3. Multiphysics

Most design optimization tools only look at a single physics domain, usually structural. However, because the finite element method (FEM) supports multiple physics, more advanced software tools use an optimization process that can find optimal solutions for multiple types of loading and results. Common multiphysics topology optimization software combines structural, structural dynamics, heat transfer, and fluid flow in a single optimization problem.

4. Design Parameters

Users can also drive their designs toward more practical solutions by defining design parameters that can vary within an assigned range. These may be as simple as a list of standard hole sizes or a range for corner radii, or as complex as nonlinear material properties, minimum spacing between features, or moments of inertia.

5. Manufacturing Constraints

The inclusion of manufacturing constraints is the one of most important advancements in topology optimization tools. These may be the constraints of the additive manufacturing process used to build the part. For traditional milling, constraints may include minimum radii, maximum feature depth, or the elimination of overhangs. For molded parts, characteristics like minimum wall thickness, draft angles, and overhangs are often specified.

6. Material Property Variations

One area related to, but distinct from, topology optimization is material property variation. Users can specify a range of continuous variables or a list of discrete variables for the optimization algorithm to factor into its optimization algorithm.

The Advantages of Topology Optimization

Topology optimization has evolved into a powerful design tool because it frees engineers from the limitations of a predefined shape. Instead of starting with a best-guess geometry and modifying it to meet design requirements, topology optimization adds and removes features based on the loads the object experiences. This approach delivers some specific, measurable improvements:

- Lightweighting: The primary advantage of TopOpt is removing as much material as possible while maintaining structural integrity. This reduces both mass and the amount of material used.

- Improved performance: Because topology optimization algorithms shapes the topology to meet defined goals, engineers can use it to improve overall performance and efficiency.

- Faster time to market: Topological optimization is an automated process that, with sufficient computing power, can be completed fairly quickly. It also avoids the need for a trial-and-error manual design iterations, each of which would require separate simulations.

- Manufacturing method optimization: By including manufacturing constraints, topology optimization tools solve the problem of generating geometry that can’t be manufactured. Engineers are able to specify the intended manufacturing method and then optimize features accordingly, reducing cost and time.

- Exploration of alternative materials: When engineers switch to a new material, a design may require substantial changes to an object’s geometry. Topology optimization tools enable engineers to start with the old design, then swap in the new material and modify the geometry to meet design goals.

Common Applications of Topology Optimization

The most common use of topology optimization is in the aerospace industry, in which production volumes are low, performance is critical, and weight savings offer significant benefits. The first aerospace applications focused on brackets that hold heavy objects and experience significant loading, such as engine mounts.

Success in this area encouraged aerospace companies to employ topological optimization for other structural components like internal wing structures and thermal applications such as heat exchangers and heat sinks. Many of these production parts designed with TopOpt take advantage of additive manufacturing, which is well understood and well suited for aerospace applications.

Another industry embracing topology optimization is the automotive industry. Weight reduction is an important part of automobile and motorcycle design, along with the cost savings associated with using less material. Because high-volume 3D printing is still expensive, car manufacturers rely heavily on manufacturing constraints within topology optimization tools to produce geometries that can be manufactured with high-volume manufacturing processes like sheet metal bending, metal stamping, and casting.

Automotive design teams also leverage the ability to include vibration analysis in a topology optimization study to optimize the NVH performance of vehicles, avoiding vibrations that passengers can hear or feel.

The advantages of topology optimization also apply to many other industries, including wind energy and built structures. Any application that can allow the load to drive the shape of the product can benefit from topology optimization. Designers are even exploring its use for furniture design, creating organic, functional chairs and tables.

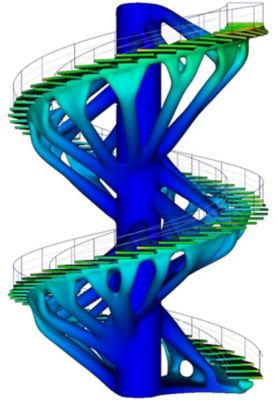

This spiral staircase design shows the organic beauty of designs generated with topology optimization.

Simulation Tools for Topology Optimization

The enabling technology behind topological optimization are simulation tools — usually finite element analysis software packages — connected to topology optimization tools that change element parameters in the model. These tools can be broken into two categories: preliminary design exploration and detailed simulation.

Fast, easy-to-use preliminary design simulation tools like Discovery software balance accuracy and speed to give design engineers rapid design exploration tools that can explore optimal shapes in near real time. Along with speed, a strong connection to CAD geometry is important for this level of topology optimization. To make topological optimization practical, modern simulation tools use GPU acceleration to achieve solution speeds up to 10x faster.

Once the design direction is established, the next step is to deploy a detailed simulation tool like Ansys Mechanical software or Ansys LS-DYNA software. These offer advanced topology optimization algorithms, a wide set of design and manufacturing constraints, and world-class Multiphysics simulation capabilities. An important part of the optimization process is to run an accurate and thorough verification simulation of the final configuration to make sure the optimized design meets all design requirements.

Related Resources

Let’s Get Started

If you're facing engineering challenges, our team is here to assist. With a wealth of experience and a commitment to innovation, we invite you to reach out to us. Let's collaborate to turn your engineering obstacles into opportunities for growth and success. Contact us today to start the conversation.