-

-

Access Free Student Software

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

-

Connect with Ansys Now!

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Countries & Regions

Free Trials

Products & Services

Learn

About

Back

Products & Services

Back

Learn

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

Back

About

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Free Trials

TOPIC DETAILS

What are Electric Machines?

Electric machines are a system of interconnected components that convert electrical energy into or from mechanical energy, or electrical energy into another type of electrical energy. They are used in many electronic systems today, from household appliances such as washing machines to medical implants and robotics. They are responsible for a large portion of the electricity generated and transmitted through power lines and other energy infrastructure. Recently, there has been an increased interest in electric machines for electric vehicles (EVs).

There are two categories of electric machines that are defined by whether part of the machine is moving or not. The first type is stationary electric machines, which have two stationary armatures and no moving part. A key example of this is a transformer. The second type is rotating or linear electric machines, such as generators and motors, which always have a moving part that operates either in rotation or translation. These electric machines have a moving part (rotor or mover) and a stationary part (stator).

As bidirectional energy systems, electric machines can theoretically convert energy either way, regardless of whether they’re a motor or a generator ― with the output being either mechanical or electrical energy.

Transformers generally fall under the category of stationary electric machines because most have no moving armatures and require no motion to transform energy. In contrast, generators and motors are dynamic electric machines that possess rotating parts and use motion to convert electrical energy to mechanical energy and vice versa. Rotational electromechanical machines generally work through the interaction between rotating electromagnetic fields, which are created by either a voltage supply or through electromagnetic induction. These rotating magnetic fields also produce torque on the mechanical side and induce voltage and current on the electrical side.

Some of the advantages of this technology include:

- Electric motors are much more efficient than other energy conversion systems like internal combustion engines (ICE), with efficiencies above 90-95% for EVs compared to 20-30% for ICE vehicles.

- Electric machines in electric vehicles (EVs) have fewer moving parts than ICE vehicles, which contributes to longer expected life cycles.

- Electric machines are zero-emission technologies.

- Electric machines are capable of bidirectional energy conversion, operating in both motoring and generating modes.

Some of the general disadvantages of electric machines are:

- Electric machines may be limited by their supply, e.g., EVs are limited by the storage capacity and charging capabilities of their batteries. This is in contrast with gasoline, which has a much higher energy density, so ICE vehicles can afford to lose 70% efficiency and still be commercially feasible.

- The electromagnetic field generated by electric machines can impact living creatures after prolonged exposure.

- The electromagnetic fields of electric devices near each other can perturb each other, as they will interact if they’re at a similar frequency. This is known as electromagnetic interference (EMI).

- There is a possible fault of electric machines short-circuiting, which can result in fires.

Electric Generators

In moving electric machines, the electromagnetic fields of the stator and rotor interact. These interactions can take the form of different configurations:

- The rotor field is self-excited (permanent magnets)

- The rotor field requires a separate electrical energy supply (wound-field synchronous motors)

- The rotor field is created via induction by the stator field (induction motors)

Any moving electrical machine can operate as a generator or a motor. When operating as generators, electric machines convert mechanical energy into electrical energy and are used in electrical power generation applications. One key application area is renewable energy generation, such as wind turbines and hydroelectric power.

Energy is typically generated through rotational motion. Although linear motion could be used, the device would be limited by its size. Rotational motion allows the moving part to move indefinitely without hitting a practical limit.

An input mechanical energy source is required to make generators move. Some common examples include a crankshaft, wind or water forces in renewable energy technologies, and steam from burning fuel and nuclear reactors. These forces drive the primary mover apparatus (such as a fan or turbine) within the generator that makes it move, converting rotational energy into a voltage and an electric current.

Generators come in different forms. AC (synchronous or induction/asynchronous) generators convert mechanical energy into alternating current and voltage. On the other hand, DC generators convert mechanical energy into direct current and voltage. In synchronous generators, the voltage is fixed to the rotational speed of the generator, whereas induction (asynchronous) generators don’t require a fixed rotor speed to match the frequency of the grid.

Electric Motors

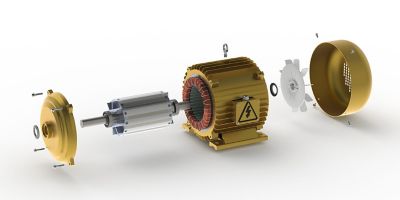

Electric machines convert electrical energy into mechanical motion when operating as motors. Motors are composed of a shaft, bearings that act as support, and a housing that encloses all the components.

Torque produced by a motor comes from the electromagnetic interaction of the stator and rotor fields. Stator windings create the rotating magnetic field, while the rotor field is created by either permanent magnet rotation, the induced electromagnetic field in rotor windings, or the rotation of electromagnets. The torque is proportional to the physical force generated by the motor, which is used to generate speed in the system it’s attached to (a vehicle, for example). Inverters are then used for speed control in the motor by controlling the frequency of the motor’s power supply to ensure it runs continuously.

Electric motor, with the stator on the right and rotor on the left. Fan and casings are shown.

Many different industries and applications use motors, with some notable ones being:

- Industrial machinery

- Vehicles

- Home appliances

- Pumps

- Fans

- Robotics

- Fitness equipment

- Drones

- Power tools

Transformers

Transformers are a type of electric machine. Instead of transforming mechanical energy to electrical energy or vice versa, they convert electrical energy from one voltage level to another with a small amount of loss. No mechanical energy conversion is involved in transformer operation, but transformers are vital pieces of grid infrastructure that allow electricity to be transported long distances over high-voltage transmission lines and then be made suitable for households in lower-voltage distribution networks.

High-voltage transformers

There are two types of transformers: the step-up transformer and the step-down transformer. Both transform the voltage of electrical energy into a different voltage.

Step-up transformers convert low-voltage electricity into high-voltage electricity ready for transmission lines. The secondary circuit in a step-up transformer is coiled more around the magnet compared to the primary circuit, raising the voltage.

Step-down transformers reduce the voltage for households and businesses. The secondary circuit in a step-down transformer is coiled less around the magnet compared to the primary circuit, lowering the voltage.

Transformers are vital because high-voltage electricity can be transported much more efficiently over long distances, but they’re too unsafe for use with everyday electronics. Electricity needs to be at a lower voltage for use, and transformers provide a means to easily change the voltage of the electricity at specific points across the electrical grid.

How Simulation Benefits Electric Machine Design

Simulation is used to improve the efficiency and performance of electric machines used across industries. Engineers use simulations in the design of electric machines to simulate the performance of both the moving and nonmoving parts of an electric machine and gain insight into the thermal, electromagnetic, and mechanical performance to ensure efficient design.

Ansys Maxwell advanced electromagnetic field solver: solves static, frequency-domain and time-varying magnetic and electric fields using 2D or 3D finite element methods. Maxwell software is ISO 26262 compliant.

Ansys Motor–CAD dedicated electric motor design tool: platform for fast multiphysics simulation across the full-torque-speed operating range. It uses embedded 2D finite element analysis (FEA), analytical calculations, and equivalent circuit methods for electromagnetic performance. It can also aid in optimizing the machine's cooling system to minimize the mechanical stress and noise, vibration, and harshness (NVH) response.

Ansys Mechanical structural FEA software and Ansys Fluent fluid simulation software: provide more detailed and tailored post-processing simulations for the physical design of an electric machine

Ansys ConceptEV design and simulation platform: dedicated tool for simulating EV powertrains. It enables system and component design engineering teams to collaborate on a shared system simulation connected to requirements from the start of the design process. This allows users to derive specifications for the electric machine design process for different vehicle architecture candidates, among other applications.

Ansys Twin Builder digital twin simulation platform: used for investigating interactions between electric machines and power electronics in a system. The electric machine can be modeled through co-simulation with software solutions such as Maxwell software or through reduced-order models (ROMs) in a virtual environment to investigate different scenarios.

To design more efficient electric machines through simulation, contact our technical team today to discover how Ansys solutions can be applied to your designs.

Related Resources

Let’s Get Started

If you're facing engineering challenges, our team is here to assist. With a wealth of experience and a commitment to innovation, we invite you to reach out to us. Let's collaborate to turn your engineering obstacles into opportunities for growth and success. Contact us today to start the conversation.