Digitalization is impacting nearly every profession, workflow, and industry worldwide. Fortune Business Insights reports that the global digital transformation market was valued at $2.27 trillion in 2023 and is expected to reach $12.35 trillion by 2032.

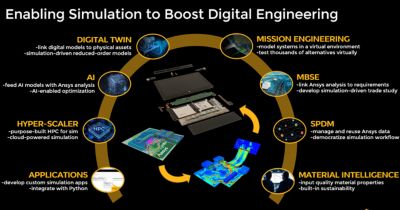

With the advent of technologies like artificial intelligence and machine learning (AI/ML), cloud computing, and simulation-powered digital twins, just to name a few, it’s no surprise that organizations are also turning to digital solutions to evolve their engineering processes.

So, what is digital engineering, why is it more important now than ever, and how can organizations enable it? To find out, Ansys interviewed some of its top simulation and industry experts to discuss digital engineering’s evolution, revolution, and what it means for simulation, industry, and engineering at large.

The Evolution of Digital Engineering

Q: What is your definition of digital engineering?

SCOTT CUNLIFFE, Manager Application Engineering, New & Emerging Technology at Ansys: Digital engineering is all about using cutting-edge technology to design, build, and manage engineering systems more efficiently, ranging from small-scale product design projects to complex industrial programs. Digital engineering integrates system architecture, digital design, physics simulations, artificial intelligence, and digital twins within a digital thread that connects engineering organizations, eliminating silos and ensuring seamless collaboration within a unified digital ecosystem. It is the art of comprehensively capturing requirements, design, verification, and validation within virtual systems to minimize physical prototypes.

Additionally, it enables real-time feedback by incorporating performance data from physical versions of the engineering product or program, enhancing its design and maintaining its performance over time.

Q: How has digital engineering changed in the last decade, and what role has simulation played in this transformation?

ANDY KO, Director, Ansys Professional Services: In the past decade, the focus has shifted from using simulation as a standalone tool to gain better insight and understanding about our engineered systems, including the efficiency of the engineering process and cost, to looking at the problem in a more holistic way. This is what is called the systems or system-of-systems view.

With that, we started emphasizing model-based systems engineering (MBSE), which is the practice of systems engineering using models as opposed to describing systems in static documents. This effort expanded to using connected engineering models and simulations to reflect the “big picture” view. It mirrors the evolution of the use of computer-aided design (CAD), with the transformation of manual 2D drawings to CAD systems, then to its use in other domains and simulations such as finite element analysis (FEA) and computational fluid dynamics (CFD).

Today, the role of simulation in engineering is commonplace. The focus now is on connecting all these disparate digital models to take advantage of the synergy from those connections but also on the shift from merely focusing and optimizing on the individual part or discipline to the performance of the cyberphysical product as a whole.

SCOTT: Notable advancements include the shift from a document-based systems approach to a fully digitized and connected set of MBSE tools, which connect the simulation analysis to validate aspects of the design, such as hardware. With the increased adoption of methodologies like MBSE comes larger and more complex simulation workflows to represent these complex systems, requiring toolchains of engineering software that need to be managed.

To address simulation process management, we have seen the rise of simulation process and data management (SPDM) systems, which store, manage, and capture simulation activity workflows. These systems fill a much-needed gap in the computer-aided engineering (CAE) world that product life cycle management (PLM) systems were not designed to handle. Complex multiphysics studies captured in SPDM can then be replicated within multidisciplinary design analysis and optimization (MDAO) toolchain software to run large-scale design of experiments (DOEs) and generate optimized results and trade studies. In other words, existing simulation analyses that are repeatable can be integrated into a toolchain to run variants of the study to find an optimized design and trade-off various parameters. Only by capturing the intelligence of these toolchains can this be done at a meaningful scale across different engineering teams.

As the complexity of simulation and such toolchains increases, the demand for high-performance computing (HPC) has been met by cloud computing, enabling remote offloading of computationally intensive studies. Additionally, AI is expanding its footprint in digital engineering, not only by analyzing legacy data to predict future outcomes, but also by using trained AI models to generatively produce new, high-performance designs.

Challenges to Digital Engineering Adoption

Q: What are some strategies to convince leadership to shift from physical-first prototyping to digital-first simulation?

RENI RAJU, Senior Manager, Technical Account Management at Ansys: To convince the leadership to shift from physical-first to digital-first for new product development, the value delivered should be aligned with their key business initiatives and connected with some key performance indicators. Key quantifiable metrics associated with a reduction in cycle times, improved efficiencies, a reduction in product or development cost, faster time to market, and reduced quality or warranty risk, etc., are some important indicators that these stakeholders care about.

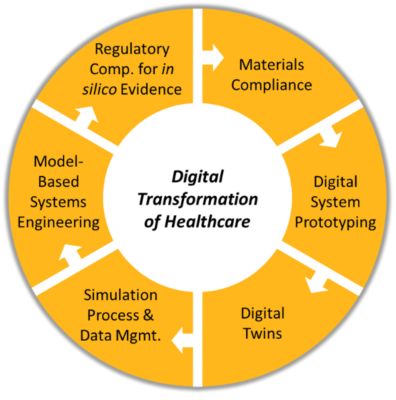

MARC HORNER, Distinguished Engineer at Ansys: The healthcare industry has traditionally relied on bench testing, animal testing, and clinical trials to understand the safety and effectiveness of devices and drugs. The regulatory requirements for conducting and summarizing studies based on these sources of evidence are well established by each country. However, time-to-market, recalls, a shift to outcomes-based medicine, and other factors are challenging the industry to achieve the competing goals of releasing safer and more effective devices at a faster pace. This is leading manufacturers to explore not only broader adoption of computational modeling and simulation tools, but also integration of simulation technology across the total product life cycle, i.e. digital engineering.

To support this transition, we are developing examples that demonstrate the power of the Ansys portfolio to enable digital engineering (see chart). This has been more of an educational exercise that has resonated with customers as a potential future state, but they still see these workflows as quite visionary.

Q: What top challenges do companies face when integrating new technologies and establishing digital engineering ecosystems?

MARC: I am finding that medical device manufacturers are still in more of an “ambition” phase when it comes to digital transformation and digital engineering. They are hiring consultants who are investigating the potential for digital transformation to provide more efficiencies and insights into their innovation processes. One of the main goals appears to be focused on ensuring that there is an enterprise-level understanding of the current state of the product design.

The pharmaceutical industry is investing in digital manufacturing initiatives to provide more reliability and robustness to their drug manufacturing processes. The goal is to eventually have digital twins that enable automated process control of drug manufacturing, which would provide both quality assurance and optimal output.

Q: How can companies maximize their return on investment (ROI) with simulation and digital engineering tools?

RENI: Many of the ROIs I mentioned earlier — reduction in cycle times, improved efficiencies, reduced product or development cost, faster time to market, and reduced quality or warranty risk — can be attributed to leveraging simulation and digital engineering tools. Beyond this, by incorporating virtualization in their product development process, companies can reduce the amount of physical testing needed to validate the product performance and compliance requirements. At the same time, by incorporating digital engineering, organizations can introduce agile product development, which allows them to rapidly evolve their designs against changing requirements, giving them a competitive advantage with a faster time to market. This is especially important when the product complexity increases. Using a model-based approach, organizations can also significantly reduce rework in recreating designs by leveraging or reusing knowledge from previous designs towards a data-centered approach.

Efficiency Benefits of Digital Engineering

Q: What is stopping organizations from capitalizing on simulation and digital engineering?

RENI: Organizations are at different maturity levels when it comes to adopting simulation and digital engineering. It is important to note that implementing digital engineering practices is not just about technology but equally about embracing change management for the organizations while considering the dynamics of people, processes, and culture. Rather than a step change, it should be seen as a maturing journey toward becoming a model-based enterprise.

Traditionally, organizations have primarily relied on physical testing as the means to validate product performance and maintain quality control. As noted previously, modeling and simulation provide significant value when used earlier in the product development process. As product complexity increases, so does the level of validation required to ensure that system performance is as-designed, as-manufactured, and as-operated. Each of these stages has multiple uncertainties associated with them that simulation and digital engineering can help address. Along with that, by applying rigorous verification and validation processes during the development process, you can increase the level of confidence in virtual models to predict system characteristics.

We are already seeing efforts underway in certain industry segments to meet compliance requirements using certification by analysis (CbA). Consideration for verification and validation of models along uncertainty quantification approaches are also being established to increase the confidence in predictions of numerical results. However, in the interim, digital engineering can bring the physical and digital results together in an efficient, collaborative workflow to improve developmental efficiencies. I can imagine that sometime in the near future, digital engineering will be able to reduce the developmental physical tests down to “getting it right the first time.”

Simulation process and data management (SPDM) tools like Ansys Minerva software enable teams to manage simulation, data, and workflows throughout their organization from one central database, creating a digital thread.

Q: What are some limitations of traditional simulation approaches, and how does digital engineering address them?

SCOTT: Typically, engineering disciplines worked in silos where, for example, mechanical teams had limited interaction or influence from electrical teams. MBSE and SPDM have unified engineering teams and have given them a common language and platform from which to collaborate. This has also eliminated the traceability problem now that the digital thread connects all disciplines at all stages of the engineering life cycle.

Simulation fidelity increases year on year, allowing for more accurate results, and the efficiency, speed, and volume of computing available further allows engineers to study models at higher fidelity than before.

ANDY: As mentioned, traditional simulation focuses on the optimization and design of the individual part or aspect of the product in question. What is best from a micro level, i.e., an individual part or aspect, may not be best for the overall product. In fact, most good products are compromises between competing individual aspects to produce the best key performance metric overall.

Traditional simulation is also usually siloed within the community of experts who use it. Hence, the use of those simulations is only limited to those few experts who know it from a deep technical level. Additionally, the management of those models and data is usually done on the local level and is not consistent, searchable, shareable, or discoverable.

Digital engineering strives to connect these models in a structured way such that the process is not only transparent but more democratized. It also shifts the focus to a holistic solution rather than a combination of individually optimized parts.

By shifting to managed data and models housed in federated authoritative sources of truth, the pertinent information required by stakeholders can be communicated much more easily and frequently. Relevant information is also more easily accessible, reducing the time engineers take to search for and retrieve it.

The Impact of Digital Engineering

Q: What are the most exciting advancements in physics-based simulation and digital engineering today?

SCOTT: AI for prediction, AI for generation, and AI for insights are the most exciting due to the speed of advancements we can achieve. But all AI solutions are limited by data management, and it is necessary to catalog the training data to be used by AI. This is where SPDM offers an exciting proposition to act as the nexus for all CAE data both upstream and downstream of the other digital engineering advancements. Digital twins are unifying the design world with the physical world and bringing engineers on both sides closer in lockstep, and it is worth mentioning NVIDIA Omniverse as an equally prospective and exciting aggregator for the visualization of all engineering assets to achieve true digital twins.

DID YOU KNOW?

Select NVIDIA Omniverse-powered features will be available for Ansys high-fidelity computational fluid dynamics (CFD) and autonomous vehicle solutions in Q3 2025, with additional applications to follow. Learn more.

Q: How do these technologies or methodologies change how we think and use simulation in the context of digital engineering?

SCOTT: Discipline with data sees an upturn across teams. With the knowledge that there are downstream consumers of simulation data, whether MBSE or hardware simulations, engineers are moving into the mindset of more accurately and intelligibly capturing their data inside digital systems. All data has suddenly become valuable as training data — simulations that failed to meet the criteria set out by the requirements are still useful as training data for AI models.

Q: How might generative design and simulation-driven engineering change how products are developed?

ANDY: Good question. In general, it should lead to better-optimized designs and better engineering insights that hopefully lead to better products. It should also reduce the development time, as fewer physical prototypes would be required. We should, however, also recognize that product development is not solely an engineering effort. In fact, engineering is but one part of the process, and decision-makers make decisions based on multiple other factors, engineering being one of them. Therefore, the role of engineering, the changes in its processes, and improvements in efficiency and design should be considered in the context of the much bigger picture of product development.

Q: How does cloud computing support accessibility and scale for simulation and digital engineering?

SCOTT: Cloud computing provides on-demand access, allowing engineers to run simulations from anywhere without the need for expensive hardware. This democratizes digital engineering, enabling organizations of all sizes to integrate advanced simulations into their workflows. The flexibility of cloud computing allows for a dynamic balance between cost and performance, where routine computing needs can be scaled as required. By leveraging “burst compute” capability, organizations can accelerate complex simulations, reducing processing time while maintaining efficiency.

Q: Are there any skills that engineers of the future need to adopt and build toward?

RENI: To enable digital engineering, engineers will have to develop diverse skill sets, focusing on two principles: multidisciplinary thinking and collaborative learning. These principles have also been captured within Ansys’ white paper “A Perspective on the Adoption of Digital Engineering Within an Enterprise.”

Multidisciplinary thinking exposes people to complementary sets of skills and knowledge that can be applied to real-world situations. This leads to an adaptable workforce capable of handling ambiguous, complex, and dynamic situations. Furthermore, multidisciplinary training can also help to identify weaknesses or opportunities in strategy, leading to more effective and efficient operations.

Collaborative learning encourages knowledge-sharing and teamwork. This approach can help the digital engineering stakeholders learn from each other’s experiences and perspectives, fostering a more collaborative and innovative work environment.

ANDY: Learn to conduct engineering with the bigger picture in mind. In other words, consideration as to how decisions would affect the entire product should be taken into account. Traditional engineering allowed engineers to live within their own silos and work to meet their own localized requirements. If it hasn’t already, this will change with focus toward a more holistic way of making design decisions.

Engineering simulation software and connecting technologies can be used to advance digital engineering.

Discover Digital Engineering at Ansys

Ansys’ comprehensive and open ecosystem of multiphysics simulation tools spans all areas of physics, while additional solutions support niche technologies and areas such as digital twins, AI/ML, and cloud computing.

Further, Ansys Connect solutions enable digital engineering more easily by linking simulation, data, and resources throughout an organization into a digital thread. These solutions include SPDM, materials management, process integration and design optimization, and MBSE.

Just for you. We have some additional resources you may enjoy.

“The focus now is on connecting all these disparate digital models to take advantage of the synergy from those connections but also on the shift from merely focusing and optimizing on the individual part or discipline to the performance of the cyberphysical product as a whole.”

— Andy Ko, director, Ansys Professional Services