-

-

Access Free Student Software

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

-

Connect with Ansys Now!

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Countries & Regions

Free Trials

Products & Services

Learn

About

Back

Products & Services

Back

Learn

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

Back

About

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Free Trials

As the automotive industry pivots toward electrification, autonomy, and compressed design cycles, computational fluid dynamics (CFD) must evolve in lockstep. Traditional simulation workflows are no longer sufficient to meet the demands of modern vehicle development, where delays can result in multimillion-dollar losses and missed market opportunities.

In response, Ansys, part of Synopsys, has redefined the CFD landscape with a suite of next-generation technologies that fundamentally transform meshing, simulation, and design exploration through graphics processing unit (GPU)-native solvers, faster preprocessing, and artificial intelligence (AI)-driven workflows.

An external aerodynamics simulation of a 500-million-cell DrivAer model using Ansys Fluent fluid simulation software solved on four NVIDIA Hopper GPUs in approximately three hours.

From Legacy Bottlenecks to High-Velocity CFD

Legacy automotive CFD workflows typically involved a linear, stage-gated approach — such as 15-month design cycles where simulation played a late-stage validation role. Today, that model is obsolete. In an era defined by software-defined vehicles (SDVs), thermal complexity, and concurrent platform development of internal combustion engines (ICEs) and electric vehicles (EVs), design teams require nearly instantaneous feedback and rapid iteration.

Product development cycles are drastically reduced by including simulation earlier in the design process and implementing artificial intelligence (AI) solutions.

Ansys has transitioned to a radically compressed, integrated workflow using GPU-native solvers, automated preprocessing, and machine learning-enhanced predictive models. Together, these advancements reduce design cycle times by up to 50% and enable simulation to lead, not lag, the design process.

Four Pillars of Next-Gen Automotive CFD

At the core of Ansys’ transformational CFD approach are four interconnected technologies:

1. Rapid Octree Meshing

The trend in modern CFD goes toward large-scale, unsteady simulations. Scale-resolving simulations (SRSs) need meshes with hundreds of millions of cells. To facilitate such simulations, massive parallel mesh generation is needed, with limited user interaction.

The introduction of scalable, automated meshing via the rapid octree meshing tool in Ansys Fluent fluid simulation software enables high-quality mesh generation for complex geometries in a fraction of the time compared with other meshing methods. Cases involving hundreds of millions or even billions of cells can be meshed in minutes.

Rapid octree meshing uses a top-down meshing approach, with no surface meshing step required. The rapid octree feature directly creates a volume mesh and projects it onto the tessellated geometry. This supports an incredibly fast, scalable meshing process while ensuring that the geometry is still accurately represented.

Rapid octree meshing is a top-down meshing approach with distinct benefits compared with bottom-up meshing.

This meshing method also minimizes computer-aided design (CAD) cleanup, intelligently localizes refinement, and seamlessly integrates with batch automation for full CAD-to-solution pipelines.

Access “Generating Rapid Octree Meshes” documentation to learn more.

A 2-billion-cell model was meshed in just 25 minutes on under 2,000 cores, enabling high-fidelity geometry evaluations at unprecedented throughput.

2. GPU-Native Solver

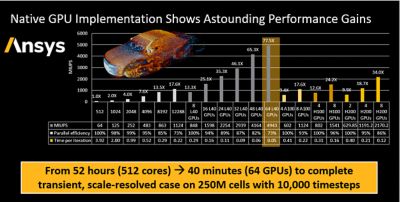

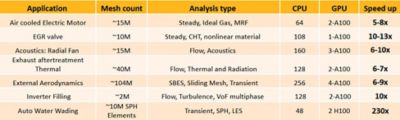

The Fluent GPU-native solver is optimized to leverage modern GPU architectures (NVIDIA, AMD, Intel) without the performance penalties of CPU-GPU offloading. This enables:

- Up to 80X speedup versus CPU-based solvers

- Seamless scaling up to hundreds of GPUs

- Comparable or superior accuracy to traditional CPU workflows

A 250-million-cell scale-resolving simulation that would traditionally take 52 hours on 512 CPU cores was completed in just 40 minutes on 64 NVIDIA L40 GPUs.

Benefits also extend beyond simulation speedups to major cost savings. One-time GPU hardware costs, combined with the electricity cost of the job, end up being significantly lower compared with running the associated CPU configurations.

A one-time GPU hardware purchase is more than two times more cost-effective than the associated CPU hardware cost.

The monthly electricity bill for eight NVIDIA Ampere GPUs is over 16 times more cost-effective than for CPU hardware.

Read the Fluent GPU Solver Hardware Buying Guide to learn more.

3. Smoothed Particle Hydrodynamics (SPH) With Ansys FreeFlow Software

Ansys FreeFlow SPH simulation software brings GPU-accelerated, meshless SPH capabilities to automotive CFD. It’s ideally suited for large-displacement liquid interactions like tank sloshing, sensor soiling, electric motor cooling, and water wading. FreeFlow software simplifies setup and reduces overall simulation turnaround times.

Multivehicle water-wading and dirt management simulations now can be executed efficiently using multi-GPU setups, enabling original equipment manufacturers (OEMs) to evaluate full-fleet behaviors in dynamic splash scenarios.

4. AI and Machine Learning

AI is changing the technology landscape, and businesses must implement AI tools to stay competitive. Ansys has introduced the Ansys SimAI cloud-enabled AI platform, which empowers engineers to generate CFD predictions in seconds using trained AI models. These models ingest historical simulation data and are accessible via a no-code web interface or Python application programming interfaces (APIs) for deep customization. Designers using the SimAI platform in Blender or design tools built with NVIDIA Omniverse™ can modify geometry and retrieve physics predictions without ever leaving their modeling environment. Engineers can also embed SimAI software into automated optimization loops or generate design-specific web apps for cross-functional teams.

- Full 3D field predictions, including nonparametric geometrical variations with near-CFD fidelity

- Drastically reduced simulation time (for example, 20-hour CFD jobs reduced to two minutes)

- Democratized use across teams (including non-CFD experts and designers)

Real-World Performance Gains

The combined impact of rapid octree meshing, GPU-native solvers, and AI translates into a profound increase in simulation throughput and accuracy:

Faster Meshing

Faster Solving

GPU-native solvers in Fluent software, Ansys Rocky particle dynamics simulation software, and Ansys FreeFlow smoothed-particle hydrodynamics (SPH) simulation software enable users to run multiple simulations and respond to simulation requests the same day.

Success at Volvo: Reducing External Aerodynamics Simulations From 24 Hours to 6.5 Hours

In March 2025, Volvo announced that it reduced its total external vehicle aerodynamic simulations from 24 hours to just 6.5 hours using rapid octree meshing on CPUs and the Fluent GPU solver on eight NVIDIA Blackwell GPUs — setting a benchmark in the automotive industry and beyond.

Volvo relies on advanced computing and CFD to drive innovation and improve electric battery performance. Robust simulations are critical for reducing aerodynamic drag — a significant factor in EV range. However, high-fidelity CFD simulations can be time-consuming, compute-intensive, and costly, and they allow little opportunity for optimization.

Volvo and Ansys scaled Fluent software to eight NVIDIA Blackwell GPUs, enabling an optimized end-to-end workflow wherein meshing took only one hour and the solver took 5.5 hours. That is a 2.5X solving speed increase compared with solving the same simulation on cost-equivalent hardware using 2,016 CPU cores. The technology combination enabled Volvo to run multiple CFD simulations per day, evaluating a range of design variants to quickly enable a step change in design optimization.

A New Era in Automotive CFD

These advancements are more than incremental; they are transformative. Ansys’ next-generation CFD workflow enables automakers to compress entire simulation pipelines, iterate rapidly on design variants, and explore vast design spaces with data-driven confidence. By fusing GPU-native solvers, intelligent meshing, SPH capabilities, and AI inferences, Ansys empowers engineers to simulate at the speed of innovation.

Learn More

Just for you. We have some additional resources you may enjoy.

If you’re ready to take your CFD simulations to the next level, make sure to join us at Supercomputing 2025 in St. Louis from Nov. 16 to 21.

The Advantage Blog

The Ansys Advantage blog, featuring contributions from Ansys and other technology experts, keeps you updated on how Ansys simulation is powering innovation that drives human advancement.