Design for Metal Additive Manufacturing Part 2: Topology Optimization and Build Preparation

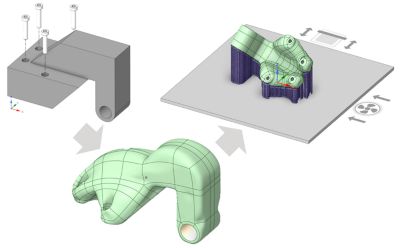

The aim of this case study (second part of a third part case study series) is to structurally optimize the component through topology optimization while ensuring a satisfactory safety margin. Furthermore, the component shall be prepared for additive manufacturing, meaning an optimal build orientation should be determined, and support structures together with machine files shall be created.

Learning Outcomes

- Ability to use Discovery to carry out topology optimization

- Ability to use Ansys SpaceClaim Additive Prep to generate a build file for print and simulation

Applicable Courses for Use

Additive Manufacturing, 3D printing, digital manufacturing, manufacturing process

Downloadable Content

- Case study report

- Simulation files