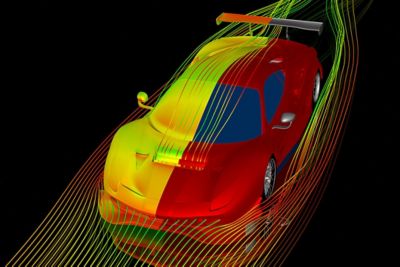

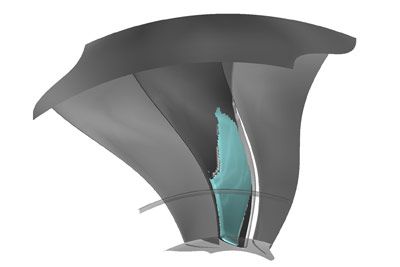

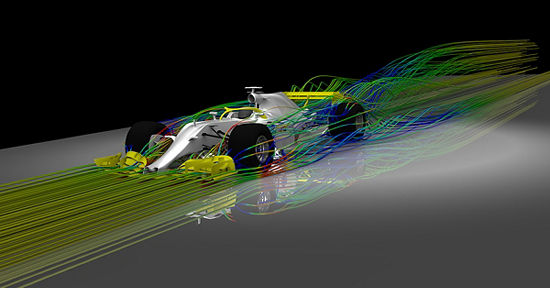

Ansys computational fluid dynamics (CFD) products are for engineers who need to make better, faster decisions. Our CFD simulation products have been validated and are highly regarded for their superior computing power and accurate results. Reduce development time and efforts while improving your product’s performance and safety.

Ansys Fluids

Computational Fluid Dynamics (CFD) Simulation Software

Fast, Accurate CFD

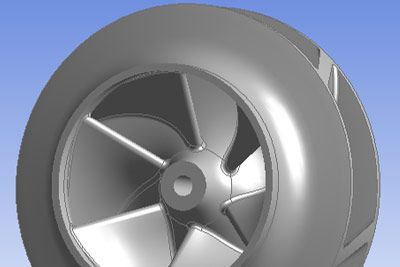

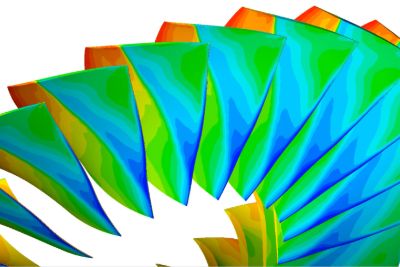

Intuitive, yet extremely powerful, our computational fluid dynamics software’s accelerate product development. Ansys CFD products give you the possibility to make incredible progress through innovation as pressures to optimize products ratchet up and margins for error narrow quickly. Comprised of the industry’s most accurate and trusted solvers, you will have confidence in your results. Whether you want to maximize the efficiency of an internal combustion engine or perform an in-flight icing simulation, Ansys has the tool for you. Maximize your time and increase productivity with modern, user-friendly Ansys CFD products.

Fluids Products

January 2025

What's New

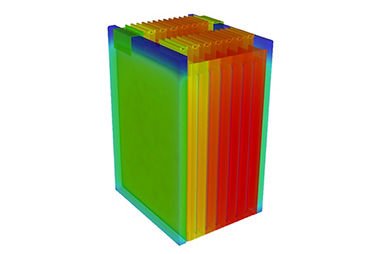

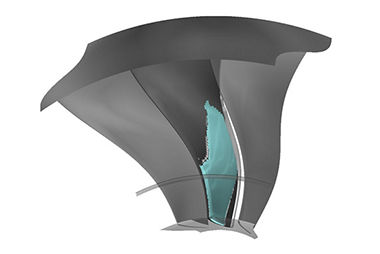

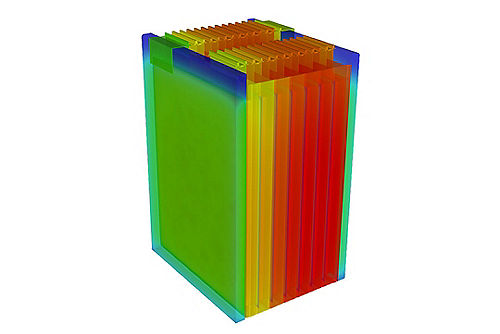

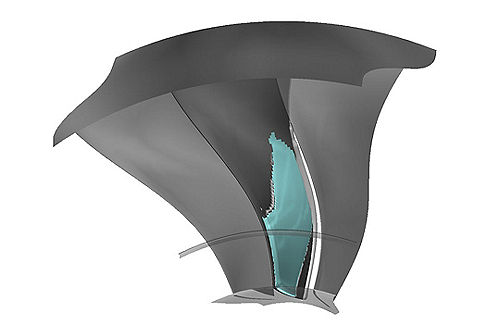

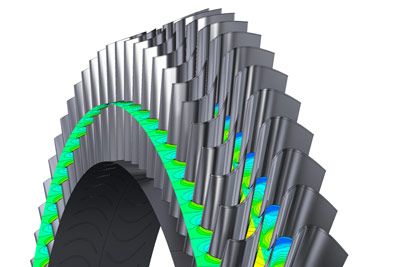

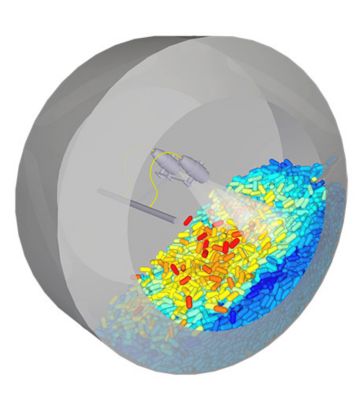

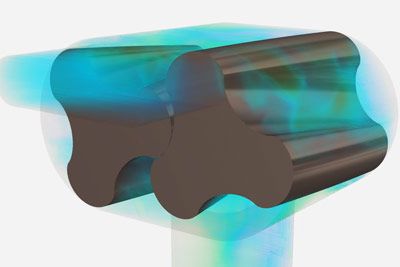

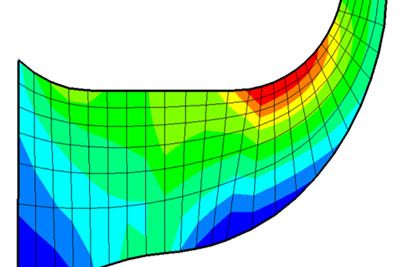

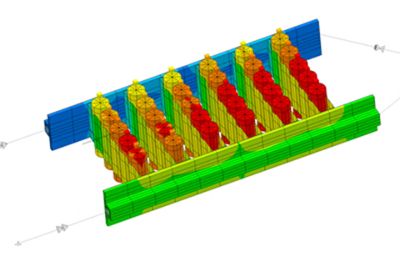

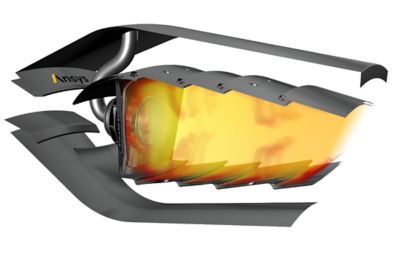

In Ansys 2025 R1, the fluids product line continues to deliver critical enhancements to meet our customers' performance and productivity needs. The Fluent GPU Solver now supports additional physics, including the FGM combustion model, particle and droplet modeling with the discrete phase model (DPM), surface-to-surface radiation, and more. Combining these new capabilities provides a complete solution for GPU-based gas turbine combustion simulations.

The recently launched Ansys Fluent Web Interface supports end-to-end workflows from meshing through solving to post-processing. Setup operations in the Fluent desktop GUI are 3-500X faster for cases with many zones, significantly reducing pre-processing times for complex assemblies. Finally, advancements across Thermal Desktop, Rocky, and CFX include dramatic performance improvements, new multiphysics integrations, and additional optimization options.

Webinars

Let’s Get Started

If you're facing engineering challenges, our team is here to assist. With a wealth of experience and a commitment to innovation, we invite you to reach out to us. Let's collaborate to turn your engineering obstacles into opportunities for growth and success. Contact us today to start the conversation.