Case Study

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Contact Us -

Careers -

Students and Academic -

For United States and Canada

+1 844.462.6797

“Top Dutch Solar Racing uses Ansys and its packages to validate the designs made by our aerodynamic engineers, the structural integrity of the components designed by our structural and mechanical engineers, but mostly for optimizing these design aspects of our solar powered electric vehicle. Using Ansys significantly decreases the resources spent on physically validating design concepts as well as tremendously speeding up the design process — allowing us to spend more time on testing our final physical product. These benefits allow the team to perform at the Bridgestone World Solar Challenge with faith in our design being as efficient as designed to be."

— Matthias van Burg, Aerodynamic and Structural Engineer, Top Dutch Solar Racing

The Bridgestone World Solar Challenge (BWSC) is a race from the north of Australia to the south, covering a total of 3021 km. It hosts three different race classes, the challenger, cruiser, and adventurer. Top Dutch Solar Racing (TDSR) participates in the challenger class, in which only one person cars race against each other. A race like this requires utmost efficiency to be the fastest, therefore it is necessary to optimize all aspects of the design.

Challenges

To ensure its solar-powered electric vehicle (SPEV) would perform well in the BWSC, TDSR needed to reduce aerodynamic drag and component weight to increase the SPEV's motor efficiency. Every two editions, the BWSC releases new regulations, which pushes participating teams to innovate on the technology used in previous years.

Engineering Solution

TDSR uses Ansys software for finite element analysis (FEA), computational fluid dynamics (CFD), and composite structure analysis purposes. Ansys Fluent CFD software helps the team increase the efficiency the most by enabling TDSR to optimize the design of the body, or aeroshell, of the SPEV without the need to validate designs physically in an iterative process. The ability to bypass physical prototyping makes the software incredibly cost efficient. Simulation of computer-aided design (CAD) models is crucial in the iterative design process of the aeroshell because it allows for rapid validation of concepts that would otherwise be left untested due to time and cost constraints.

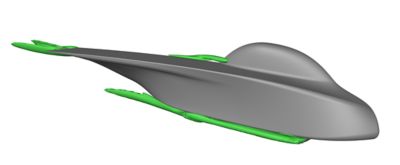

The figure above shows some elements of the turbulent wake left behind by the solar car Green Spirit. The canopy, wheels and licence plate contribute most to these turbulent wakes.

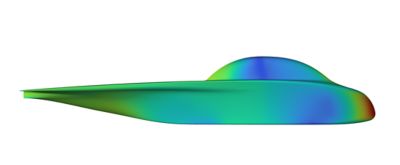

The figure above shows the pressure distribution on the solar car Green Spirit, where blue areas signal relatively low pressure areas and red areas relatively high pressure areas. The wheels and nose contribute most to the pressure drag of the solar car.

Benefits

Optimizing critical aspects of the car, in which a small percentage of improvement can make the difference is finishing the race in first or tenth place.

The most convenient benefit is that all the optimization software is in one interface.

Simulation also allows TDSR to improve on design concepts introduced in previous editions while ensuring that all regulations are being followed. By using software provided by Ansys every year, the team can improve their SPEV edition after edition.

Green Spirit in Morocco

See What Ansys Can Do For You

See What Ansys Can Do For You

Contact us today

Thank you for reaching out!

We’re here to answer your questions and look forward to speaking with you. A member of our Ansys sales team will contact you shortly.