-

Ansys는 학생들에게 시뮬레이션 엔지니어링 소프트웨어를 무료로 제공함으로써 오늘날의 학생들의 성장을 지속적으로 지원하고 있습니다.

-

Ansys는 학생들에게 시뮬레이션 엔지니어링 소프트웨어를 무료로 제공함으로써 오늘날의 학생들의 성장을 지속적으로 지원하고 있습니다.

-

Ansys는 학생들에게 시뮬레이션 엔지니어링 소프트웨어를 무료로 제공함으로써 오늘날의 학생들의 성장을 지속적으로 지원하고 있습니다.

ANSYS BLOG

February 14, 2022

Disconnected Engineering Is Costing You Time and Money — and Impeding Innovation

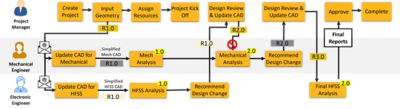

At Ansys, we’re firm believers in the power of engineering simulation. We recognize that simulation cannot be an isolated step in the process run by a group of specialists in their silos. The product development team uses multiple tools every day to get your designs to market. From product life cycle management (PLM) software to computer-aided engineering (CAE) and design (CAD) solutions, your engineers, designers, and project managers are leveraging an advanced toolkit of best-in-class technologies that, in theory, should be tightly integrated and working toward a common purpose. The problem? Too often, these tools are not integrated. At all.

In many product development organizations, simulation, CAE/CAD, and PLM solutions are disconnected, used by different functional groups, and fed by different data streams. Because each tool is generating its own huge volume of noncentralized data team members are working with multiple versions of the truth, wasting time searching for files, making mistakes, and engaging in rework.

For example, imagine one of your designers made an important change to a CAD file that was saved to a PLM system database, but the simulation analyst wasn’taware of the change. In this scenario, the analyst would have run a large, numerically complex simulation that was based on the wrong data, which would require the simulation to be re-run when the error was caught later. Or, in a worst-case scenario, no one would have noticed the error until the cost-intensive physical prototyping stage — or until the product failed in the field.

This scenario probably happens more than you think, as many teams rely on inexact, error-prone manual handoffs and email notifications instead of automatically updating CAE/CAD files and other key data across the entire technology ecosystem. Team members are doing their best using disconnected tools and communicating manually across functional boundaries, but the end results include wasted time, unnecessary costs, the potential for a missed launch date, and the bigger risk of warranty claims and product recalls.

In today’s hyper-competitive, extremely fast-paced development environment, your organization can’t afford to let this kind of process roadblock impede your speed to market, product quality, and innovation — especially when there’s a straightforward, cost-effective, purpose-built solution.

Create a Shared Ecosystem for a Single Version of the Truth

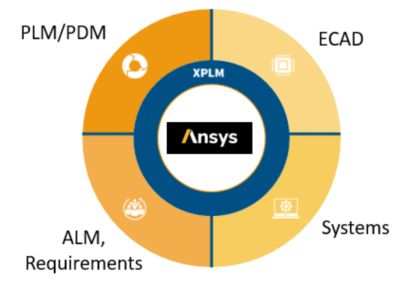

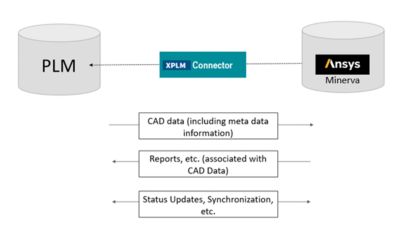

Ansys Minerva is an enterprise-level simulation process and data management (SPDM) solution that supports the integration and interoperability of Ansys simulation software with CAE/CAD, PLM, and other engineering tools your team is using in its everyday work.

Built on an open architecture, Minerva combines engineering solutions from diverse vendors in an integrated ecosystem. It provides a common platform for your team’s end-to-end development and analysis of product designs, supporting seamless cross-functional workflows and process handoffs.

By connecting disparate, disconnected tools and systems, Minerva enables your team to seamlessly pass data back and forth while enabling automatic, universal updates and complete data traceability. Your organization’s enormous data volumes — generated by Ansys solvers and other sources — are configured, synchronized, and searchable, resulting in higher-quality information and a single version of the truth.

Because Minerva is tightly integrated not just with Ansys solvers, but also with other engineering solutions, it creates a central, accessible repository for all simulation-related data, along with their context. When engineers search for a file, that search is executed across all the data stored in multiple systems Minerva is linked with. All users can be confident they’re working with the most up-to-date information at all times, minimizing mistakes and rework while maximizing innovation.

Discover the Power of a Connected Digital Thread

The fact that your product development team is leveraging multiple best-in-class solutions is not a disadvantage — and there’s no need to “rip and replace” your existing systems and tools. These advanced solutions just need to be connected and integrated with one another to deliver greater speed, efficiency, and cost effectiveness.

Developed by Ansys, the acknowledged leader in engineering simulation, Minerva is a purpose-built solution that’s designed to deliver integration and interoperability. By directly connecting simulation and analysis to the larger product life cycle, Minerva creates a powerful digital thread that ties together the entire end-to-end development process.

The best way to decide if Minerva is the right integration and interoperability solution for your team is to request an assessment. Get ready to see the real speed, cost, and quality advantages of using Minerva to create a robust technology ecosystem within your organization — and a meaningful competitive advantage.

당신을 위한 Ansys 솔루션을 알아보십시오.

당신을 위한 Ansys 솔루션을 알아보십시오.

문의하기

문의해 주셔서 감사합니다!

여러분의 질문에 답변해 드리기 위해 최선을 다하겠습니다. Ansys 담당 엽업이 곧 연락을 드릴 것입니다.