Quick Specs

Polyflow lets you investigate plastic and elastomer behavior and determine the best manufacturing approach. Optimize products prior to full production runs and reduce prototype attempts.

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

For United States and Canada

+1 844.462.6797

Ansys Polyflow is a finite-element based CFD software used to reduce the cost of polymer, glass, metals and cement processing.

Ansys Polyflow accelerates design time while shrinking energy and raw material demands for manufacturing processes. Polyflow helps to investigate the behavior of new plastics and elastomers. Virtual prototyping enables optimization and design exploration to reduce waste and overdesign.

Polyflow lets you investigate plastic and elastomer behavior and determine the best manufacturing approach. Optimize products prior to full production runs and reduce prototype attempts.

Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries

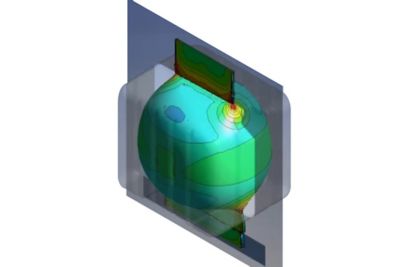

Engineers utilize Polyflow to minimize water container costs and maintain product integrity.

Performing blow-molding simulation as well as structural analysis provides a method for companies to ensure reliability. Changes made to the manufacturing process can be directly related to final part performance through simulation.

In high-volume manufacturing, such as water containers, a minor reduction in material can drastically reduce costs and improve profit over time. However, reducing material can be risky without testing and design validation. Polyflow is the perfect software to analyze extrusion blow molding and simulate product behavior before any manufacturing attempts.

In order to validate their design and material reduction efforts, Gamma Point engineers used Polyflow’s simulation tools specialized for polymer. Being able to predict manufacturability and simulate how the bottles will handle various stresses is extremely useful. This virtual method proved to be much more efficient than a time consuming “trial and error” approach.

Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries

Ansys Polyflow contains high-performance solvers dedicated to polymer simulation. It is able to solve nonlinear material deformations and even has a novel meshing technique to distinguish tools from working materials. This is especially helpful for die design and can help you predict performance or reveal unexpected problems. The combination of these tools allows engineers to accurately simulate complex material behaviors and rely less on expensive and wasteful trial and error methods.

Accurately predict material behavior and optimize your manufacturing processes with application-tailored simulation software.

Packaging is important to protect products from damage — but it is also a sustainability issue, as well as an additional cost to goods suppliers. Deploying a virtual prototyping using Polyflow enables you to model the package manufacturing process. By coupling this solution with Ansys explicit dynamics software and Ansys Mechanical, your R&D team can evaluate and test a design's behavior and durability. You can take corrective action at the design or manufacturing phase (or both) to quickly and cost-effectively design lighter packaging with better performance.

Ansys PolyFlow allows companies to virtually design and test extrusion dies. Users can simulate the extrusion process and automatically perform die shape optimization. As a result, they are able to:

Ansys Polyflow includes a vast library of mathematical material models so you can understand and accurately characterize material behavior. Using the Polyflow material library, you can investigate behavior of new plastics and elastomers for applications as diverse as extrusion, blow molding, thermoforming, fiber spinning and film casting. Simulation enables you to test the ability to process new resins, even before they have ever been produced, by comparing prototypes for different materials to see if they match or outperform existing and competitive materials. You can reverse-design a resin to maximize end-product performance while minimizing costs and environmental impact.

Ansys Polyflow models include viscous heating to allow you to detect potential deterioration of a polymer grade or undesired rubber curing. Accurate modeling of high-temperature processes, such as glass forming, requires the use of advanced nonlinear material properties, accurate radiation prediction (using, for example, the discrete ordinate radiation model) and the Narayanaswamy model that accounts for material stress relaxation during the cooling process.

Ansys Polyflow includes native fluid–structure interaction (FSI) to model thermomechanical interactions between flowing materials and surrounding solids in a fully coupled approach. When large deformations occur within the elastic zone, the mesh resolution is automatically refined to improve the quality of results.

You can significantly reduce time to market by seamlessly exporting Polyflow results to Ansys Mechanical software to perform structural analysis. Using the data within Ansys explicit dynamics tools, you can conduct virtual drop tests and calculate top-loading deformation.

Designing equipment and processes for best results involves evaluating multiple designs and optimizing flow and geometric parameters. With Ansys Polyflow, you can declare any scalar as an optimization variable, including rheological parameters, boundary conditions and mesh displacements. Then you can use the built-in optimization algorithm to automatically minimize or maximize a given objective function based on input parameters.

It's vital to Ansys that all users, including those with disabilities, can access our products. As such, we endeavor to follow accessibility requirements based on the US Access Board (Section 508), Web Content Accessibility Guidelines (WCAG), and the current format of the Voluntary Product Accessibility Template (VPAT).

We’re here to answer your questions and look forward to speaking with you. A member of our Ansys sales team will contact you shortly.